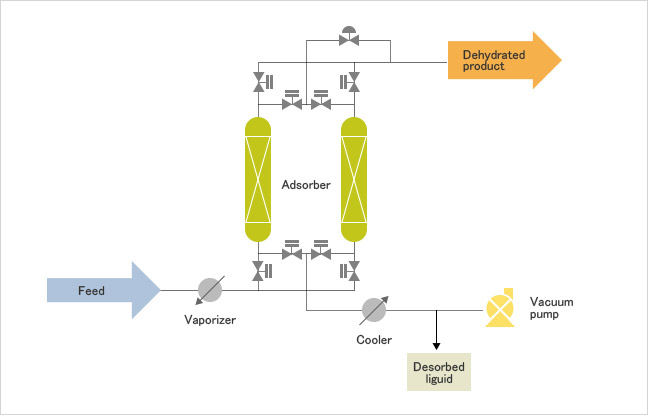

Advanced Dehydration Process for Organic Compounds (Vapor-Phase PSA System)

The process shown schematically in the figure is an advanced dehydration process for purifying organic compounds, designed to achieve high-performance dehydration through cyclic operations of adsorption at nearly atmospheric pressure and desorption at reduced pressure using two or more adsorbers. This process has realized flexibility in operating conditions and savings in utility consumption.

Features

- Needs no third component like an entrainer, nor a high-temperature heat source, as required for other dehydration processes like azeotropic distillation or temperature swing adsorption

- Easy operation (shutdown and re-startup)

- Advanced dehydration (H2O content less than 100 ppm)

Applications

- Dehydration of organic compounds that form azeotropes with water, in particular

- Ethanol, isopropyl alcohol, tetrahydrofuran (THF), etc.

Experience

- Dehydration of ethanol: 1 unit

- Dehydration of isopropyl alcohol: 2 units

- Dehydration of THF: 4 units

Energy Transition - Gas/Oil/Chemicals

- The World's Most Advanced Energy-saving Condensate Desulfurization Process(JUSTTM Condensate)

- Integrated Hydrogen Desulfurization System - JUST® Refinery -

- Gas Oil Ultra-Deep Desulfurization Process

- Dimethyl Ether (DME) Synthesis Process

- High-Purity Hydrogen Sulfide Production Process

- DTP® Process

- Advanced Dehydration Process for Organic Compounds (Vapor-Phase PSA System)

- High-Throughput and High-Efficiency Extraction Column (WINTRAY®)