Pyrolysis

Aiming for High Recycling Rates and Maximum Utilization of Existing Facilities

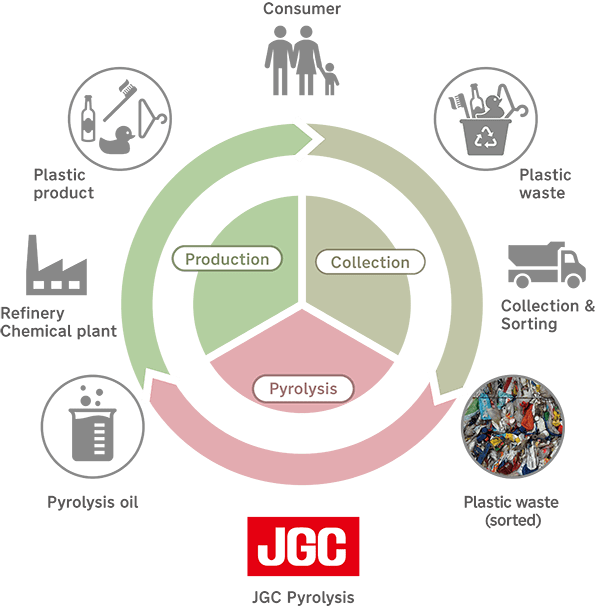

Pyrolysis process expects high recycling rate to plastic and has the advantage of minimizing initial capital investment by maximizing the use of existing facilities in refineries and petrochemical plants.

The pyrolysis technology applied by SPR can treat not only polyethylene (PE), polypropylene (PP) and polystyrene (PS) but also polyvinyl chloride (PVC) in plastic waste without sorting at pretreatment unit and perform safe and stable continuous production of pyrolysis oil by properly discharging the residue.

SPR has a track record of being operated commercially for a 10-year period from 2000*, with an annual processing capacity of 15,000 tons. The JGC Group considers this is the most reliable of all pyrolysis technologies.

With the foundation in its technological superiority and track record, the JGC Group will strive to further improve the economic efficiency of pyrolysis technology by increasing capacity of equipment and optimizing overall process system and the Group plans to begin licensing in 2022.

For chemical recycling with pyrolysis, it is important how effectively the pyrolysis oil can be supplied to existing facilities in refineries and chemical plants and then converted to plastic products.

The Group will make proposals that will contribute to enhancing the added value of client's plant by utilizing its outstanding engineering skills and sophisticated project management capabilities that it has accumulated in petrochemical refining and petrochemical projects up to now.

- *The former Sapporo Plastic Recycling Co. Ltd (SPR) recycled annual 15,000 tons of plastic waste for 10 years from 2000.

Source: Ministry of the Environment WEB site

Related News Releases

Related Business Areas

Open the Way of Recycling for Hard-to-Recycle Plastics

Realization of Fiber-to-Fiber Chemical Recycling

Promoting Production of Sustainable Aviation Fuel