Realizing a Sustainable Society

To help build a sustainable society, JGC Group is commercializing environmental technologies we have developed independently and with partners.

For a closer look at initiatives we are pursuing, click a solution in the illustration.

Forestry and Agriculture

Resource Utilization

Waste Plastic Pyrolysis

Chemical Recycling

Waste Plastic Gasification

Chemical Recycling

Zero Emission Fuel

CCUS

-

- HiPACT

- EOR

- DDR Membrane

- CCS

Polyester Fiber

Chemical Recycling

Zero Emission Fuel Production

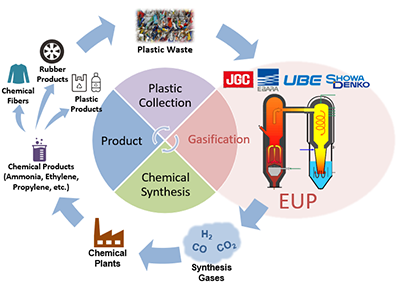

Waste Plastic Gasification Chemical Recycling

As the world confronts issue in waste plastic recycling, JGC is supporting gasification chemical recycling, which gasifies and converts waste plastic to synthetic gas that can be used in chemicals such as ammonia or olefins. Even hard-to-recycle plastics containing dirt or impurities can be recycled to create chemical raw materials that are as good as new. This improves the rate of plastic recycling and helps enable a highly recycling-oriented society.

Related News Releases

- Accelerating the Promotion of Gasification Chemical Recycling of Plastic Waste - Conclusion of an EUP Relicensing Contract-

- JGC Receives Order for Feasibility Study toward Realizing South Korea's First Plastic Waste Gasification Recycling Plant

- Study toward the development of a regional low carbon hydrogen model based on waste plastic gasification recycling in urban areas" selected by NEDO as a commissioned project - Targets the promotion of domestic hydrogen supply and plastic recycling for decarbonization -[PDF:252.5 KB]

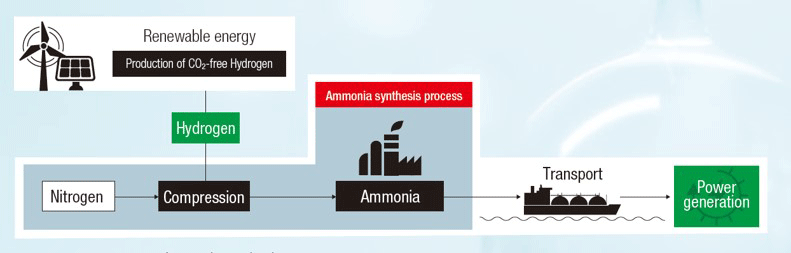

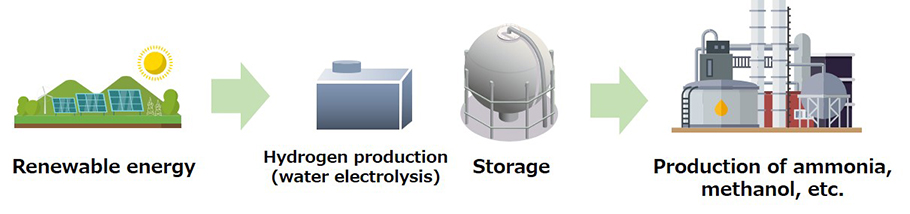

CO2-free Ammonia

In efforts toward a low-carbon society, we can anticipate expanded use of hydrogen energy, which does not emit CO2 during combustion. However, many commercial challenges remain. Economically, large-scale and efficient conversion to an energy carrier for transport is needed. An ideal choice for a hydrogen energy carrier is ammonia, which does not emit CO2 when burned. Ammonia is easily liquefied, stored, and transported, besides holding much potential as a fuel itself. JGC is engaged in developing technologies along these lines.

Related News Releases

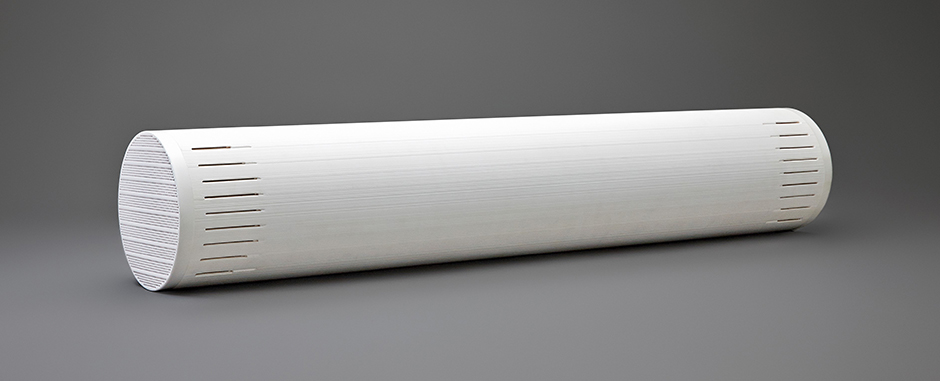

Carbon Capture and Recovery Using DDR-type Zeolite Membranes

JGC is jointly developing a high-efficiency CO2 separation and recovery technology applying DDR-type zeolite membranes with NGK Insulators, Ltd. Taking this approach - separation and recovery of CO2 from associated gas during crude oil production or natural gas treatment - contributes to the promotion of CO2 recycling and energy resource development.

HiPACT

HiPACT®plant

NIS a.d. Novi Sad (Serbia)

HiPACT technology absorbs and separates CO2 in natural and synthetic gas, enabling recovery under high pressure. Using this technique in applications such as carbon dioxide capture and storage (CCS, which involves underground CO2 storage) and enhanced oil recovery (EOR, which reduces crude oil viscosity and improves permeability by injecting CO2 into oil reservoirs) greatly reduces the new energy needed for underground storage. As a result, it can help curb global warming.

Related News Releases

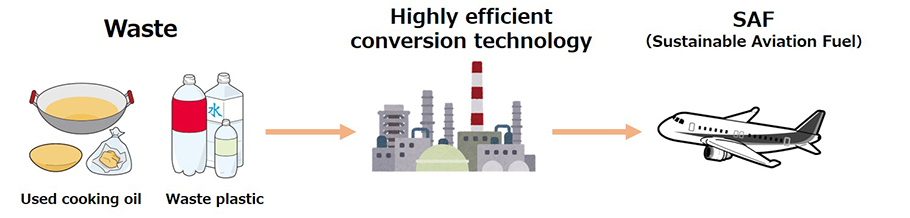

Production of Sustainable Aviation Fuel

In aviation, reducing operational CO2 emissions remains a pressing issue. Expectations are growing for the development and stable supply of sustainable aviation fuel (SAF) produced from industrial waste and other sources. JGC is studying production of SAF derived from sources such as used cooking oil and waste plastic, with an eye to establishing manufacturing infrastructure and value chains.

Related News Releases

- Start of the Study to Build a Value Chain for Sustainable Aviation Fuel with Used Cooking Oil as Feedstock[PDF:163.6 KB]

- Feasibility Study on Production and Sales of Sustainable Aviation Fuel Made from Plastic and Other Waste Materials[PDF:221.9 KB]

- "Establishment of a Supply Chain Model for Bio-jet Fuel Production from Domestic Used Cooking Oil" Selected as a NEDO (New Energy and Industrial Technology Development Organization) Project[PDF:265.3 KB]

- Establishment of "ACT FOR SKY" a voluntary organization working for the Commercialization, Promotion and Expansion of Domestically Produced SAF[PDF:245.5 KB]

- Basic Agreement Concluded on Cooperation to Commercialize Domestic SAF – The first large-scale commercial production of SAF in Japan is to start in 2025 using waste cooking oil from the three airports in Kansai –[PDF:431.4 KB]

- SAFFAIRE SKY ENERGY LLC Established for the First Large-Scale Domestic Production Of SAF[PDF:338.8 KB]

- Basic Agreement Concluded with Mitsubishi Estate on Cooperation to Reuse Used Cooking Oil in Domestic Sustainable Aviation Fuel (SAF)[PDF:332.8 KB]

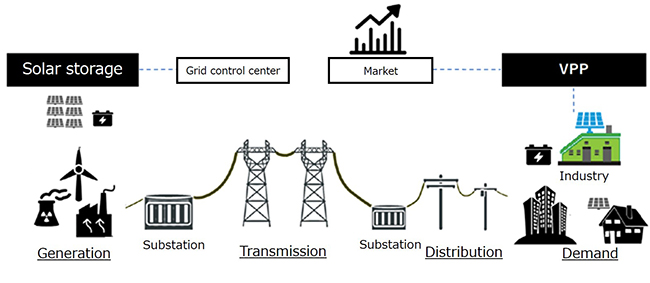

Development of Virtual Power Plants

In the quest to reduce CO2 emissions, power grid problems such as output fluctuations and excess power generation have emerged following progress in introducing renewable energy sources that have variable output depending on weather conditions. This has driven demand for economical ways to stabilize power grids. JGC is developing virtual power plants (VPPs) that aggregate surplus power from sources such as storage batteries and factory facilities to distribute it as needed in response to fluctuations in renewable energy output.

Related News Releases

CO2-free Hydrogen

As the world pursues a low-carbon society, we expect to see expanded use of non-CO2 emitting hydrogen energy. Hydrogen can be produced in various ways. In particular, the JGC is involved with a CO2-free method of producing hydrogen (green hydrogen) with electricity derived from renewable sources such as solar power. We will meet a broad range of green hydrogen demand, in areas from renewable power plant construction to hydrogen production and storage to the next stage in this development: expansion to ammonia, methanol, and other chemicals as well as methanation and fuel cell applications.

Related News Releases

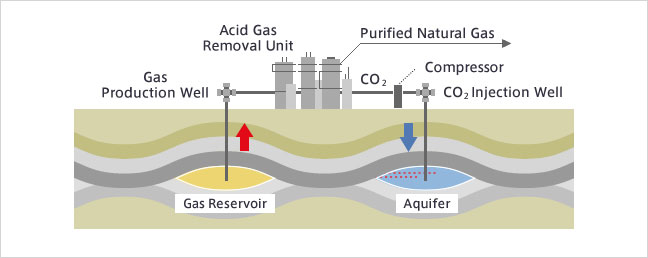

Carbon Dioxide Capture and Storage (CCS)

With CCS, CO2 from plants, factories, power stations, or other sites is captured before atmospheric release, transported through a well and injected in layers distributed deep underground that are suitable for geological sequestration. This technique for stable long-term storage is viewed as a potentially effective approach to curbing CO2 emissions and global warming. Stored in reservoirs at depths of 1,000 m or more, the CO2 must be trapped under a thick and fairly impermeable layer of mudstone or similar material. Carrying out CCS projects requires a high degree of technical expertise, and with JGC's proven record in Japan and other countries, we help clients make these plans a reality.

Related Projects

Related News Releases

- Commencement of Feasibility Study for the First Southeast Asia CCS Demonstration Project in Gundih Indonesia

- Technical Survey on CO2 Capture and Consolidated Utilization from Large CO2 Emission Sources, a NEDO-selected Project

- INPEX and JGC Partner with PTTEP to Explore Carbon Capture and Storage Project

- JGC CORPORATION and Kawasaki Kisen Kaisha, Ltd. Joins CCS Study in Malaysia

- JGC and JX Partner with PETRONAS to explore Carbon Capture and Storage Project

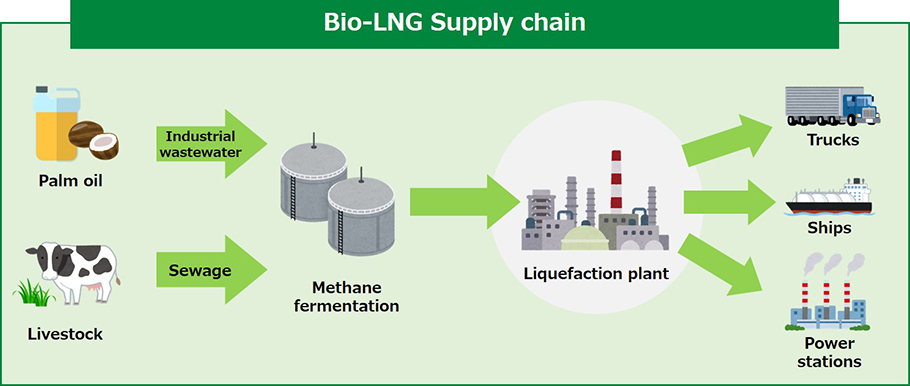

Green LNG (Bio-LNG)

Bio-LNG is a sustainable biofuel obtained from liquefaction of biogas generated from methane fermentation of organic waste.

Offering nearly 80% lower CO2 emissions than conventional LNG from fossil fuel, bio-LNG interests many as a promising approach to decarbonization of marine fuels in particular. Besides establishing economical bio-LNG production processes, JGC is looking into the formation of related value chains.

- *Life cycle assessment (LCA) basis

Biofuel

By processing bioethanol and vegetable oils to suit the application, various types of biofuel can be produced, including gasoline, aviation fuel, diesel, and marine fuel. JGC is developing second-generation bioethanol synthesis using inedible resources that are highly effective at reducing CO2 without competing with food needs.

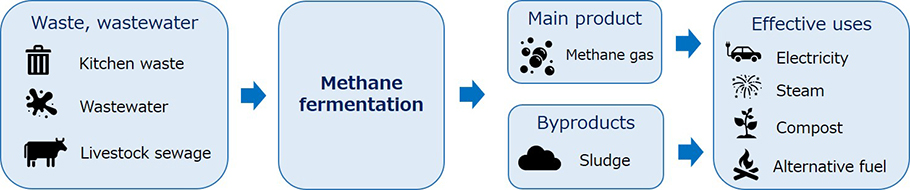

Biogas

Sludge, kitchen waste, and livestock sewage is broken down with microorganisms to produce methane gas, which is then used for heat, electricity, or fuel. Group company Swing Corporation proposes optimal applications for biogas, drawing on techniques of methane fermentation developed over many years in sewage treatment business.

Related News Releases

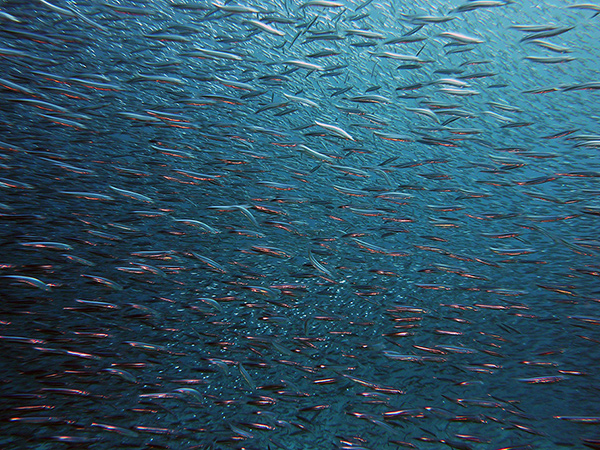

Fishmeal Replacements (Methane to Protein)

A shortage of fishmeal, used as feed in aquaculture, has been exacerbated by increased demand for marine products, especially in emerging economies. This has driven the need to develop sustainable alternatives. Focusing on large-scale culturing of single-cell protein using bacteria that feed on methane, JGC's research may pave the way to establish supply chains for a sustainable fishmeal replacement.

Home Fuel Cell/Battery

Used in conjunction with solar or other renewable energy, these storage batteries enable efficient operation overall. For example, electricity generated and stored during the day can be used at night. By supplying optimal storage batteries as energy management system and virtual power plant resources, JGC helps stabilize renewable energy output, coordinate supply and demand, and support disaster preparedness.

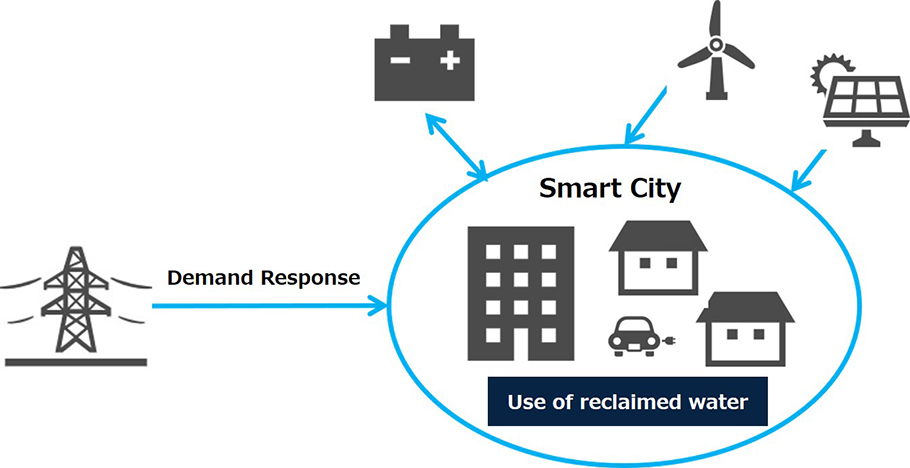

Smart Cities

For the smart cities envisioned by JGC, we are pursuing development of sustainable cities through the introduction of approaches such as local zero-carbon energy production and supply, which includes renewable energy sources, and demand response, which saves energy by adjusting demand to suit supply levels. These cities will also be built to continue functioning in the event of emergencies. After disasters, energy storage systems will maintain the power supply, and wastewater reclamation and well-water systems will ensure a supply of water for everyday needs.

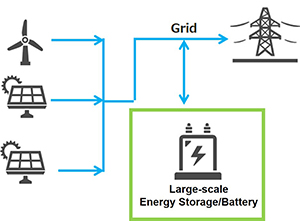

Large-scale Energy Storage/Battery

Large-scale energy storage systems coordinate energy use on a larger scale. For example, electricity generated from renewable energy sources can be stored and mainly supplied in the evening when demand spikes. By improving energy storage performance, JGC is pursuing development of large units that can respond to seasonal fluctuations in demand.

Energy Recovery (Solar Storage)

Solar-generated DC power is converted to AC before being supplied to the system, but output suppression control is needed to address frequency instability from fluctuating output due to weather conditions and other factors. This leads to the problem that the amount of power generated is suppressed, compared to capacity. Solar storage developed by JGC maintains solar power generation capacity while enabling recovery of electricity from a storage battery, which contributes to a higher total amount of power generation.

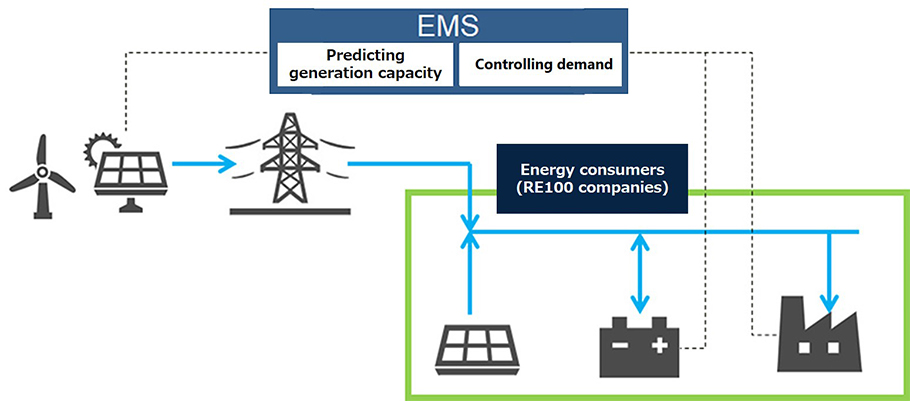

Energy Management Systems

Energy management systems (EMS) can both predict the amount of power generated from renewable energy sources and control storage battery charging and discharging. EMS provided by JGC enable efficient power supply by coordinating the amount of power expected to be generated with the supply-demand gap on the demand side.

Plant Factories

Through large-scale greenhouse cultivation, plant factories offer a stable, safe, and reliable supply of produce that meets market needs regardless of weather conditions. In Russia, JGC has established a plant factory value chain from seed registration to management of produce stands. Promotion of a vegetable brand meaning "new day" in Russian builds on Japanese standards of quality.

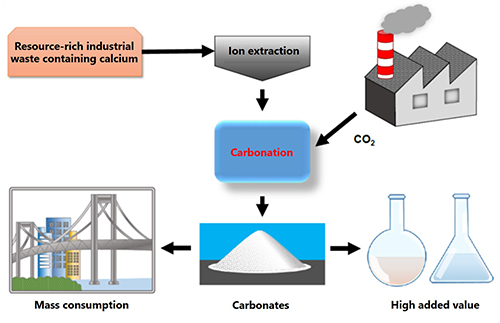

CO2 Mineralization

JGC is developing technologies to produce carbonates through a reaction between calcium and magnesium ions extracted from waste materials (such as waste concrete and desalination brine, which is twice as concentrated as seawater) and CO2 from thermal power plants or other sources. Potential benefits sought include effective use of waste and conversion of CO2 to a stable mineral that also serves as a useful industrial raw material and building material.

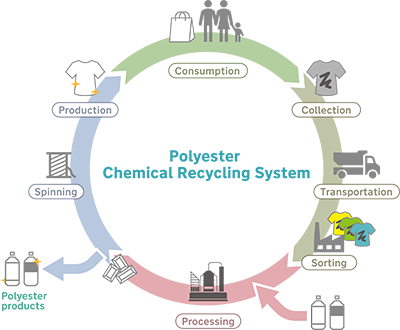

Polyester Fiber Chemical Recycling

Recently, the textile industry also faces an urgent necessity to solve sustainability issues, such as the problem of the mass disposal of clothing and the environmental impact of the manufacturing process including CO2 emissions.

The JGC Group is collaborating with companies that have a proven track record of commercial operation and a broad network in the textile and fiber industries, and will work with them in the licensing and deploying of polyester chemical recycling technology.

Related News Releases

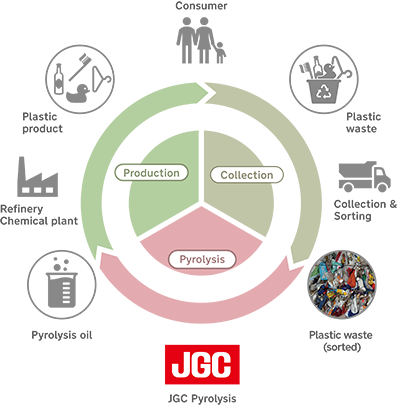

Waste Plastic Pyrolysis Chemical Recycling

In chemical recycling, the pyrolysis process creates a high recycling rate to plastic and has the advantage of minimizing initial capital investment by maximizing the use of existing facilities in refineries and petrochemical plants.

The JGC Group is developing and supporting the licensing process for waste plastic pyrolysis chemical recycling, based on large-scale equipment that has been in commercial operation in Japan for 10 years.

Related News Releases

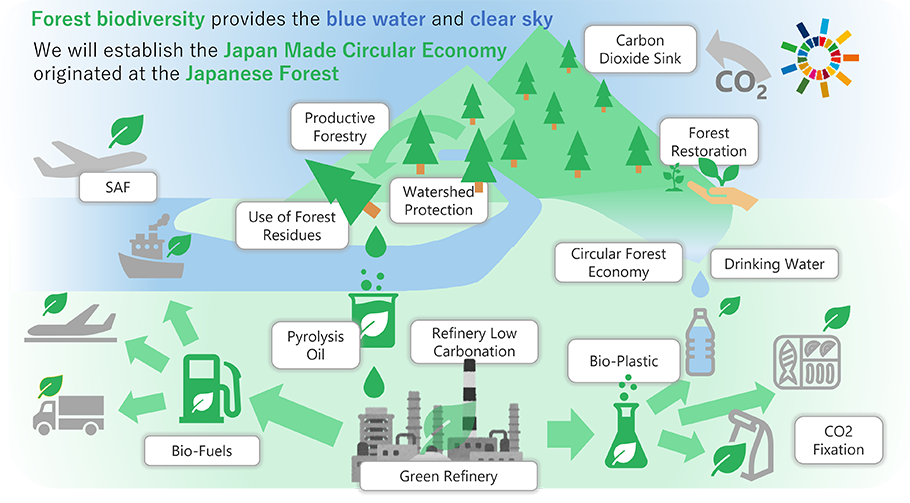

Forestry and Agriculture Resource Utilization

The JGC Group is promoting a green refinery business by building a supply chain sequence covering the collection of unused forest resources, and the manufacture of pyrolysis oil from the thermal cracking of woody biomass, through to the manufacture of bio products such as biofuels and biomass plastic raw materials made from pyrolysis oil.

Related News Releases

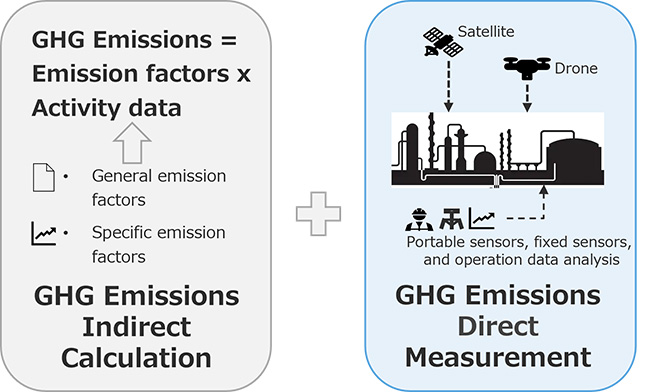

GHG Emissions Quantification from O&G Facilities

In order to reduce GHG emissions, it is necessary to first understand the current GHG emissions. In particular, facilities that handle natural gas have a large impact on the environment due to its characteristic of emitting relatively large amount of GHG, so there is a growing awareness of the need for a method that better reflects the actual operating condition. The JGC Group analyze existing international GHG emissions calculation methods and investigate and formulate GHG emissions calculation methods that are in harmony with international standards. Additionally, we investigate and evaluate methane leakage measurement technologies using satellites, drones, and infrared cameras, and provide "HiGHGuardTM " as a service for GHG Emissions quantification.