Gasification

Open the Way of Recycling for Hard-to-Recycle Plastics

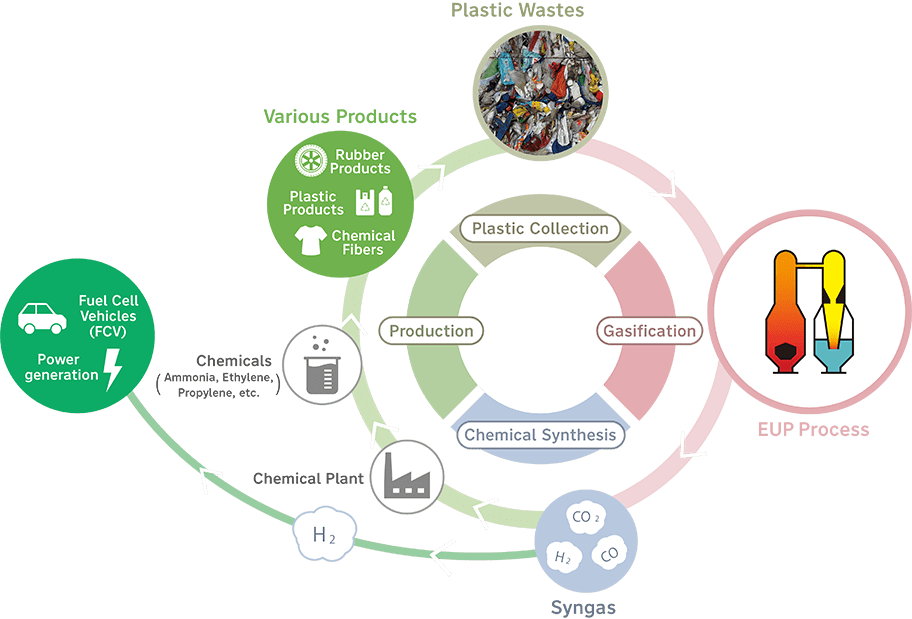

Gasification Chemical Recycling enables recycling of hard-to-recycle plastic by decompose plastic waste into the molecular level and synthesize recycled chemicals with virgin equivalent quality. Ebara Ube Process (EUP)* is the only technology in the world with a p track record of long-term commercial operation in gasification chemical recycling applications. As an official licensor/contractor of EUP the JGC Group have been engaged in the licensing and construction of facilities and equipment.

In the "gasification chemical recycling", various plastic waste which includes hart to recycle plastic can be converted to methanol, ammonia, propylene, olefins, and other chemical products. The chemical products produced through gasification chemical recycle has equivalent quality to virgin products derived from petroleum or petroleum derivatives. In addition, hydrogen for local consumption can be produced from local plastic waste. Gasification chemical recycling can contribute to building circular economy for plastic as well as building a hydrogen society.

- *EUP (Ebara Ube Process) : The EUP, which was developed by EBARA CORPORATION (transferred this business to Ebara Environmental Plant in 2009) and UBE Corporation in 2000, is a process that gasifies plastic waste using partial oxidation with oxygen and steam, and produces synthesis gases that can be utilized in synthesis of ammonia, olefins and other chemicals.

A gasification facility steadily operating at Showa Denko's Kawasaki Plant (annual plastic waste processing capability: approximately 70,000tons) since 2003 applies EUP.

Related News Releases

- Accelerating the Promotion of Gasification Chemical Recycling of Plastic Waste

-Conclusion of an EUP Relicensing Contract- - JGC Receives Order for Feasibility Study toward Realizing South Korea's First Plastic Waste Gasification Recycling Plant

- "Study toward the development of a regional low carbon hydrogen model based on waste plastic gasification recycling in urban areas" selected by NEDO as a commissioned project

-Targets the promotion of domestic hydrogen supply and plastic recycling for decarbonization- [PDF:253KB]

Related Business Areas

Aiming for High Recycling Rates and Maximum Utilization of Existing Facilities

Realization of Fiber-to-Fiber Chemical Recycling

Promoting Production of Sustainable Aviation Fuel