Integrated Hydrogen Desulfurization System -JUST® Refinery-

JUST® Refinery (JGC Unitized Smart Tailored Refinery) is a stand-alone refinery concept which, by employing new technologies, enables a 30 % reduction of CAPEX over conventional refineries with similar functions, thereby improving the IRR by 5 %. Whereas conventional refineries need multiple hydrogen desulfurization systems for each fraction (naphtha, kerosene, gas oil), the JUST® Refinery has integrated the hydrogen desulfurization systems into a single system for the combined stream.

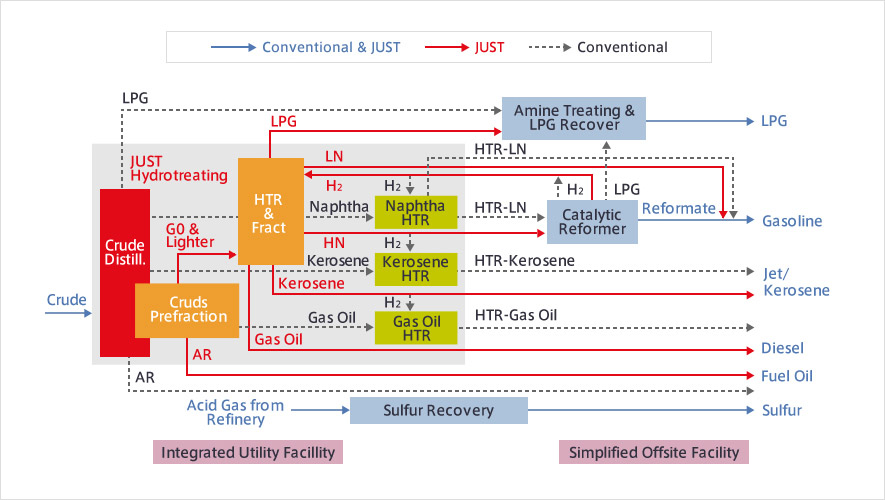

Flow Scheme (Conventional vs JUST Refinery)

In this process, crude oil is firstly fractionated into gas oil and lighter fractions and a residue. The gas oil and lighter fractions are hydrotreated all at once in one Hydrotreater (HTR) to meet the sulfur specification of each product. After hydrogen desulfurization, the gas oil and lighter fractions are further fractionated into LPG, light naphtha, heavy naphtha, kerosene, and gas oil. The heavy naphtha fraction is processed through a catalytic reforming unit to produce a reformate for gasoline blending. Hydrogen produced at the catalytic reformer is used for Hydrotreater, therefore, JUST® Refinery has a system of hydrogen self-sufficient. Moreover, the integrated utility facility and a simplified offsite facility also contribute to reducing the total refinery CAPEX and OPEX. Sulfur in product gas oil specified in Basic Design Package is less than 50 ppm. Furthermore, pilot test results have shown that sulfur in product gas oil could be less than 10ppm, depending on the raw material, for instance when it consists of condensate accompanying natural gas.

Features

Compared with a conventional refinery

| Process units required | 30 % reduction |

|---|---|

| No. of HTR main equipment | 65 % reduction |

| No. of offsite tank | 55 % reduction |

| Initial investment | 30 % reduction |

| Area required | 35 % reduction |

| Internal rate of return (IRR) | 5 % Increase |

Applications

- Grassroots refinery

- Expansion and modernization for existing refineries

- New installation of a desulfurization facility required to treat a new kind of crude oil

Related Materials

Energy Transition - Gas/Oil/Chemicals

- The World's Most Advanced Energy-saving Condensate Desulfurization Process(JUSTTM Condensate)

- Integrated Hydrogen Desulfurization System - JUST® Refinery -

- Gas Oil Ultra-Deep Desulfurization Process

- Dimethyl Ether (DME) Synthesis Process

- High-Purity Hydrogen Sulfide Production Process

- DTP® Process

- Advanced Dehydration Process for Organic Compounds (Vapor-Phase PSA System)

- High-Throughput and High-Efficiency Extraction Column (WINTRAY®)