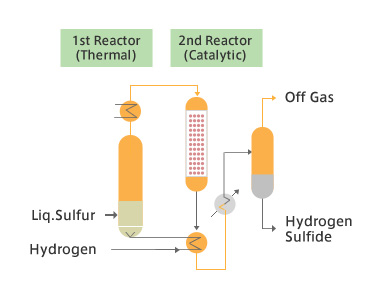

High-Purity Hydrogen Sulfide Production Process

Hydrogen Sulfide (H2S) is widely used as raw material for synthesis of a number of sulfur-containing compounds.

JGC hydrogen sulfide production process produces high-purity (≧99.9 %) H2S by the reaction of hydrogen and sulfur. The production plant is compact and ensures easy and safe operation for the production of highly toxic hydrogen sulfide.

High-purity sodium hydrosulfide (NaSH aqueous solution) is also easily produced by the reaction between hydrogen sulfide and sodium hydroxide.

Schematic Flow Diagram of Production Units

Features

- High-purity products

- Compact and economical production plants

- Lower cost and better safety than purchasing H2S

- High-performance and long-life catalyst for 2nd reactor

Applications

- Engineering plastic (PPS)

- Amino acid (methionine)

- Non-ferrous metal refining

- Pharmaceuticals

- Cosmetics

Experiences

- Hydrogen sulfide production : 2+1 (design in progress) units

- Sodium hydrosulfide production : 4+1 (design in progress) units

Award

- Technology Award of The Japan Petroleum Institute (2000)

Energy Transition - Gas/Oil/Chemicals

- The World's Most Advanced Energy-saving Condensate Desulfurization Process(JUSTTM Condensate)

- Integrated Hydrogen Desulfurization System - JUST® Refinery -

- Gas Oil Ultra-Deep Desulfurization Process

- Dimethyl Ether (DME) Synthesis Process

- High-Purity Hydrogen Sulfide Production Process

- DTP® Process

- Advanced Dehydration Process for Organic Compounds (Vapor-Phase PSA System)

- High-Throughput and High-Efficiency Extraction Column (WINTRAY®)