Sustainability Initiatives

Hydrogen energy is expected to take off over time as a viable path toward a decarbonized society.

Contributing toward the hydrogen economy, the JGC Group brings together a wide range of internal and external technologies, including original ammonia solutions developed from our AMUSETM initiatives.

A Viable Path toward a Decarbonized Society

Hydrogen's absence of CO2 emissions as a fuel positions it for future growth. But from the standpoints of economy and safety, what's needed is conversion to an energy carrier* efficient for transport and storage. In addition, commercial challenges must be resolved.

- *Hydrogen cannot be efficiently stored or transported over long time and distances as a gas. Thus, an energy carrier in this context refers to a means of efficiently storing and transporting hydrogen as a liquid or a hydrogen compound.

Able to Support all Hydrogen Carriers

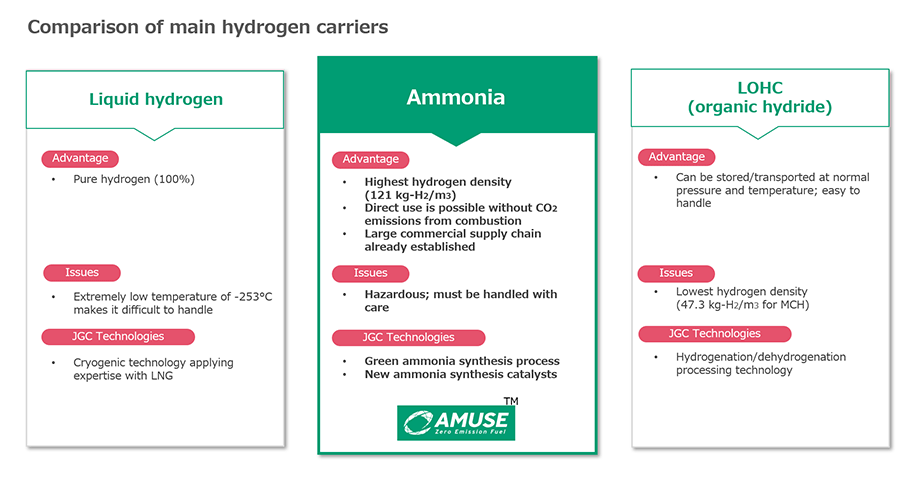

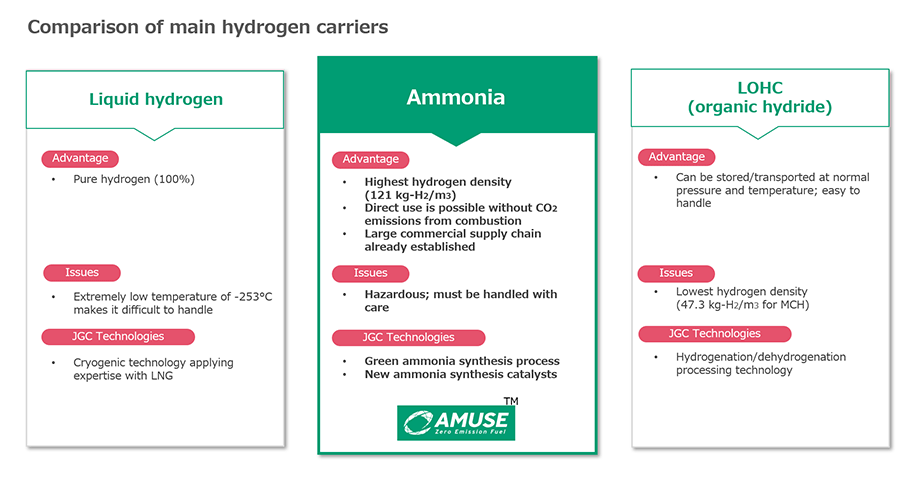

As progress is made in technical development enabling practical adoption of hydrogen carriers, the JGC Group stands out for being able to work with all three of the most promising carriers. Ammonia (NH3) in particular offers distinct advantages, with the highest hydrogen density among these carriers and extensive supply chains already established.

Relatively easy to be handled, ammonia can be liquefied at -33℃ under atmospheric pressure, or at room temperature under 8.5 atm. Its use in fertilizers and other applications already makes it one of the most common chemical substances worldwide. It also does not emit CO2 during combustion. Widespread direct use as a fuel can therefore be expected. Annual demand is projected to grow to about 3-5 million tons by 2030 in Japan alone.*

- * Source: Ammonia Roadmap, Clean Fuel Ammonia Association

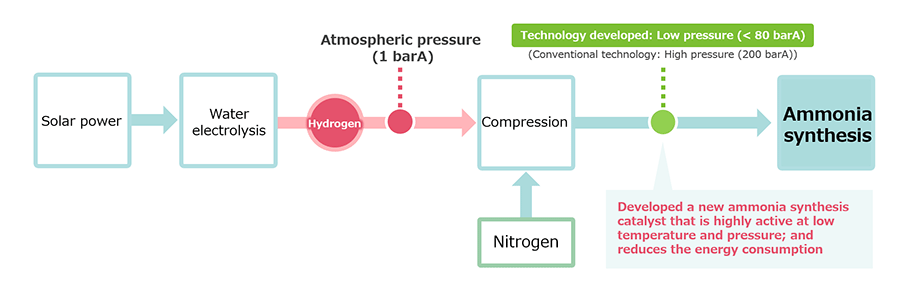

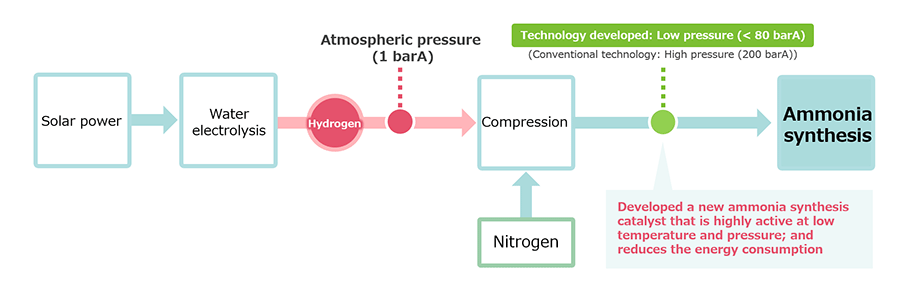

World's First Successful Green Ammonia Synthesis and Power Generation

The JGC Group and Japan's National Institute of Advanced Industrial Science and Technology (AIST) marked a joint success in demonstrating a green ammonia* value chain. In this world-first, hydrogen was produced from solar-powered water electrolysis, ammonia was synthesized at low temperature and pressure, and 47 kW was generated by an ammonia gas turbine.

- *Ammonia synthesized from hydrogen that is obtained through a process such as water electrolysis powered by renewable energy and nitrogen that is separated from the air

Development of Green Ammonia Production Technology

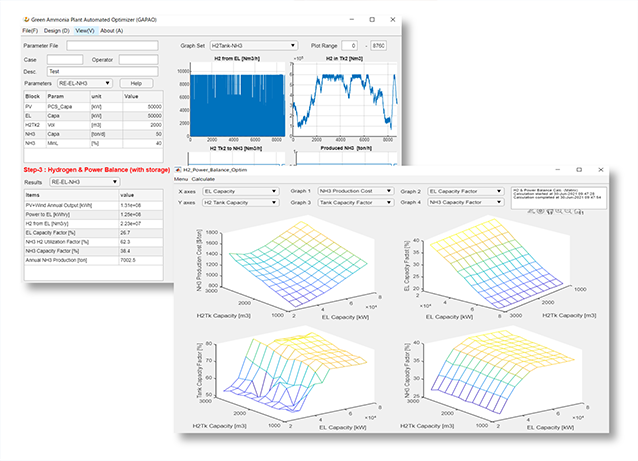

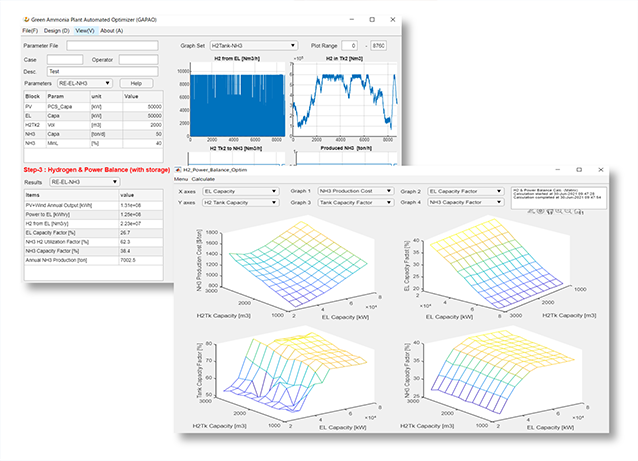

In the production of green ammonia, the plants used, including renewable energy, water electrolyser, hydrogen tanks and other equipment must be designed in such a manner as to provide appropriate capacity to have the ability to function in spite of the fluctuating nature of the renewable energy used.

The JGC Group has developed GAPAOTM (Green Ammonia Plant Automated Optimizer) software to optimize the configuration of green ammonia plants. For renewable energy sources that exhibit a variety of power generation profiles depending on location, season, and type, we will contribute to the reduction of production costs by implementing appropriate capacity design, taking into account equipment and construction costs.

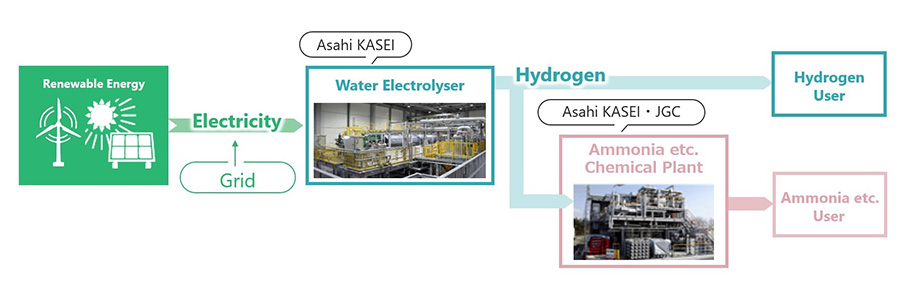

Launch of Green Chemical Plant Demonstration Project Using a Large-Scale Hydrogen Production System

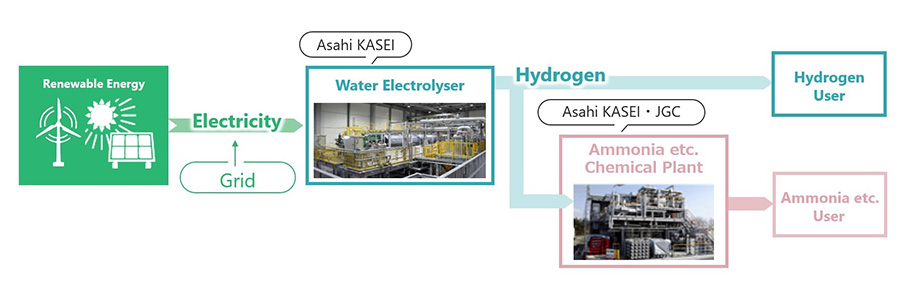

To ensure that the hydrogen-related technologies it has cultivated over the years can be applied in society more quickly and reliably, the JGC Group, in collaboration with Asahi Kasei Corporation, will take part in the launching of a green chemical plant demonstration using a large-scale hydrogen production system as part of the Green Innovation Fund project implemented by NEDO*.

Through this project, we will develop and demonstrate a system to control the hydrogen supply rate and optimize the operation of chemical plants in processes using hydrogen derived from renewable energy sources, which are subject to fluctuations, as the raw material.

- *NEDO: New Energy and Industrial Technology Development Organization

World's First Testing in Preparation to Transport Blue Ammonia

Green ammonia from renewable energy is being developed along with blue ammonia.* Blue ammonia is also expected to see more widespread use in the future. The JGC Group has participated in a pilot project in Saudi Arabia aimed at establishing a blue ammonia supply network to Japan, as promoted by the Institute of Energy Economics of Japan and Saudi Aramco.

- *Ammonia produced from fossil fuels. Ammonia can be produced in a CO2-free process applying techniques such as CCS (which captures the CO2 by-product and stores it underground) and EOR (enhanced oil recovery).

AMUSE TM

The JGC Group is actively engaged in developing technology to promote ammonia as a hydrogen carrier and fuel. Our collective name for these initiatives is AMUSETM (Ammonia Use as a Sustainable Energy), and we are working with other companies and research institutes to pioneer ammonia production projects in Japan and overseas.