MixGen®

JGC's Gas Engine Power Generation System

Realizes Maximum Utilization of Boil-Off Gas (BOG) from LNG Receiving Terminals

With increasing populations and ongoing global economic growth, LNG's status as an important energy source that constitutes a sustainable and stable energy supply is steadily expanding. Moreover, the advent of natural gas produced from low-cost shale gas is accelerating the expansion and diversification of the LNG business. Against this background, LNG receiving terminal construction projects are being implemented in various parts of the world.

Under these circumstances, we consider that, in the LNG receiving terminal construction business, realization of a system which will contribute to reducing the receiving terminal operating costs and securing a power supply source in the event of emergencies is an important factor which will greatly affect our future success in the LNG business. Further operating cost reduction is desired by operators of existing LNG receiving terminals who are trying to make their products more competitive in the LNG market.

In LNG receiving terminals, Boil-Off Gas (BOG) is constantly generated from LNG storage tanks.

JGC considers effective use of BOG as one of its new strategies for the LNG business and has established its own Gas Engine Power Generation System "MixGen®" which is a rational BOG utilization system for LNG receiving terminals.

Outline of the MixGen® System

In conventional LNG receiving terminals, BOG has been sent out as product gas after compression or has been returned to the storage tanks after reliquefaction. On the other hand, the MixGen® system uses medium-pressure BOG directly as fuel for its gas engine generator and realizes the creation of a new electric power source and the recovery of obtained thermal energy (in the form of steam and hot water).

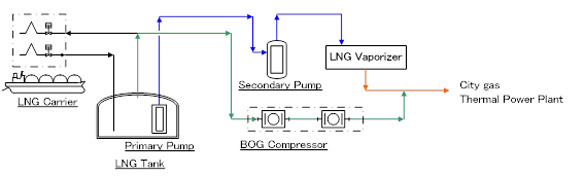

BOG Utilization Flow in Conventional LNG Receiving Terminals

Generated BOG is compressed to a high pressure level for use as feed for city gas production or for use as gas turbine fuel for combined cycle power generation.

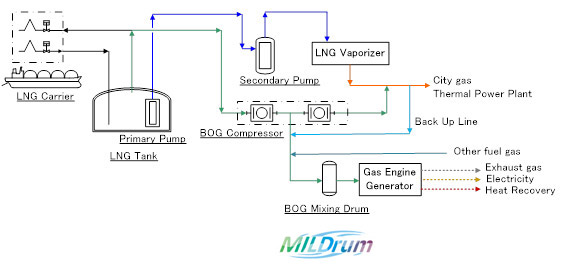

BOG Utilization Flow Using MixGen®

Medium-pressure BOG is extracted from the line between the BOG compressors (or BOG which meets the service requirements is obtained otherwise) and used as fuel for the gas engine power generation. In this system, there are several choices according to the volume of generated BOG or the needs to be met: for instance, using the total volume as fuel for the gas engine, using surplus BOG as gas products after pressurization, using extracted BOG mixed with LNG Vaporizer outlet gas as fuel for the gas engine, or using other gas as fuel for the gas engine.

Key Technologies in MixGen®

MixGen® uses BOG of inconsistent composition and various other gases as fuel in a gas engine generator. To ensure stable operation without placing too much stress on the gas engine generator even when the gas composition changes dramatically, JGC developed MILDrum®, a unique BOG adjuster to mitigate sudden changes in gas composition. MILDrum® is a key technology of MixGen®, and it is a drum that allows mild blending of fuel gases of different composition. It dramatically mitigates sudden changes in the amount of heat generated after changing the composition of BOG as the result of switching from BOG to a backup line (natural gas) or LNG, and ensures the sustainable and stable operation of gas engine generators. MILDrum® can also be used with other fuel gases, such as biomass gas, as well as fuel oil.

Merits in Introducing MixGen®

Introducing MixGen® makes it possible to use the generated electric power for purposes within the LNG receiving terminal. At the same time, the generated electric power can be supplied to the market as a stable source of electric power. Additionally, highly efficient energy recovery can be realized; for instance, the thermal energy obtained (steam and hot water) can be effectively used as a heat source for LNG and LPG vaporization within the receiving terminal.

As described above, MixGen® enables the effective use of low-cost medium-pressure BOG for power generation and conversion to steam and hot water. In addition to these advantages, MixGen® has many other merits:

- Reduces LNG receiving terminal operating costs

- Keeps down power generation business operating costs by selling the generated electric power in the market and utilizing LNG receiving terminal infrastructure

- Realizes power generation within an existing LNG receiving terminal through the use of a manufacturer-standard gas engine generator that requires only a short construction period

- Functions as an independent power source for use as part of power supply reinforcement measures that can help to cope with demand in the event of a disaster