HARview®

Innovation for Air Control in Air-Cooled LNG Plants

HARview®, a novel engineering tool developed by JGC, is a key component of AIRLIZE LNG®, our total engineering services scheme to support the Air-cooled LNG plant life cycle.

By combining "Weather Simulation*1" which reproduces the weather conditions around the plant site and "CFD*2 Simulation" which predicts the degree of HAR*3 that may occur, accurate and detailed plant design to mitigate HAR has been made possible.

HARview® is JGC's innovation in Air Control for Air-cooled LNG plants.

- *1developed by JAPAN NUS Co., Ltd. (JGC Group)

- *2CFD: Computational Fluid Dynamics

- *3HAR: Hot Air Recirculation

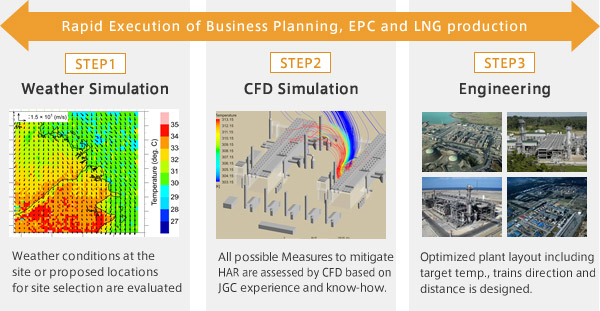

HARview®STEPS

STEP1: Weather Simulation

The weather conditions around the plant site are reproduced by the use of published weather data from near the site. The weather data such as wind direction, wind speed and air temperature can be determined with high reproducibility.

STEP2: CFD Simulation

CFD Simulation is conducted with the reproduced weather conditions from STEP 1. Since reproduced weather data which represent the actual conditions at the site are used as input to the CFD analysis, the hot air flow around the LNG plant and temperatures near equipment can be evaluated. Simulation results are used to study and analyze the occurrence and degree of HAR in detail.

STEP3: Engineering

Plant layout and operating conditions to mitigate HAR are determined based on the CFD simulation results from STEP 2. Moreover, the engineering precision is improved by repeating STEP 2 and STEP 3, and the design of an economical LNG plant with optimized production can be realized.

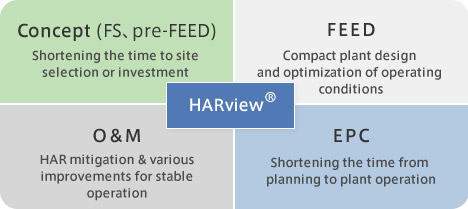

Advantages of HARview®

The engineering done using HARview® has led to drastic advancements in Air Control for Air-cooled LNG plants. The utilization of HARview®, which helps to visualize the weather conditions and risks of HAR, brings various advantages to the plant life cycle.

Concept (FS, pre-FEED) Stage

There is no need for actual measurement of the weather data at the site, so the time required

for the investment decision can be shortened.

FEED Stage

Since the plant layout is designed based on the HAR risk evaluation, a more compact plant can be proposed.

EPC Stage

EPC can be completed in a shorter amount of time by optimizing the equipment and ACHE layout.

The time to plant start-up can be shortened.

O&M Stage

Sustainable and stable LNG production is realized by HAR mitigation plans based on accurate

HAR analysis data for the plant.