AWP(Advanced Work Packaging)

What is AWP

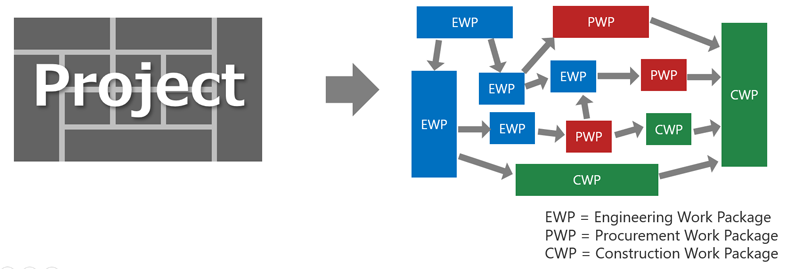

AWP, "Advanced Work Packaging" was proposed by the Construction Industry Institute (CII) in the United States in 2011. Primary objective of applying AWP is to improve productivity and reducing costs in construction phase. The Path of Construction is established at the beginning of the project based on which the project is divided into manageable units (=Work Packages), and a network schedule is created. This is a method to set constraints such as drawings, materials, resources, etc., in advance and to plan , execute and manage the project proactively. The method itself is the actual EPC project management method of the Construction & Commissioning driven approach that JGC has been executing for a long time, and is the strength of JGC group in project execution.

JGC's AWP x Data Centric EPC Project Execution

The JGC’s AWP is introduced as a further development of the AWP proposed by the CII. The keys to this method are as follows:

- 1.Business efficiency and productivity can be improved by standardization and digitalization of EPC business operations

- 2.E-P-C information can be centrally managed by implementing Tag Master/DATA Hub with the Data Centric EPC philosophy. Information reliability and real-time performance can be improved.

- 3.Schedule, cost, quality, safety, and risk management can be improved by realizing higher-level AWP execution and EPC project execution.

Defining these methods as "AWP x Data Centric EPC", JGC can deliver transparent project execution such as offering clients CAPEX-minimal project costs, providing quality and performance safely and on schedule. This allows us to help our clients by optimizing project execution formation and business plans and by realizing seamlessly handover operations. We also achieve reductions in environmental impact through optimal project execution.

AWP x Data Centric EPCとProject Digital Twin

Digital Twin is the model created in virtual reflecting the objects in the real world.

JGC has established the Project Digital Twin system as part of the "AWP x Data Centric EPC" project and is developing further advancement.

DATA Hub

DATA Hub is JGC's in-house system that integrates and manages EPC project data using WBS and Tag/Asset as the key.

It plays the role of a hub and spoke that coordinates and synchronizes the following EPC systems. It enables to centralize all EPC data, to improve reliability of information, and to update data timely.

Engineering Management

EMS

EMS is a management system for engineering data. It enables to perform engineering work efficiently using plant design data between each discipline through one platform.

In addition, by linking EMS with design software, the latest data is always stored in the EMS and shared between each design department so that drastically speeding up and improving the quality of design work. EMS is one of the important systems for the introduction of Generative Design which proposes multiple design ideas in a short period of time along with quantitative indicators, and for the automation of engineering work.

J-Driven®

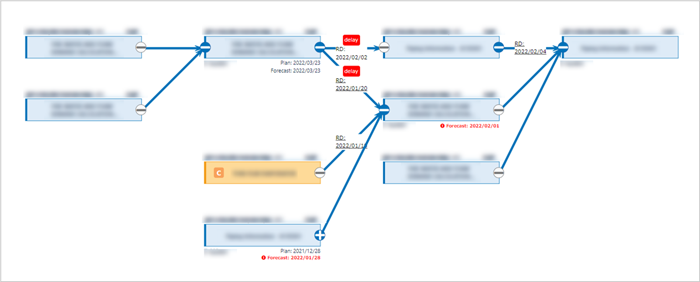

J-Driven® is a management system for the EWP (Engineering Work Package) and PWP (Procurement Work Package) created in AWP execution. In addition to managing the status of each EWP and PWP, it enables to see the bottlenecks in project at a glance, that are difficult to recognize in large-size projects by displaying the network of each work packages using J-Driven® function. Real-time identification of bottlenecks in the workflow helps elimination of them at the early stage and high quality project execution.

Example of Work Package Network on J-Driven®

Construction and Turnover Management

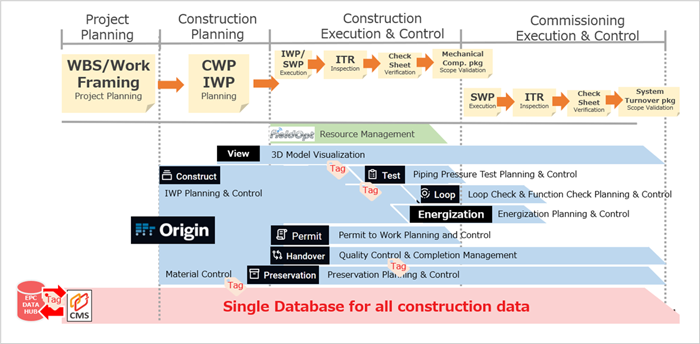

JGC Construction and Turnover Management System consists of three core systems: CMS, Origin®, and FieldOpt®. The system has been established to enable seamless digital management through the following phase: startup phase (WBS/Work Package setting), planning phase (Path of Construction, IWP unit schedule in accordance with the project master schedule), execution management phase (construction and inspection), the testing phase, the commissioning phase, and the handover phase. (See Figure 2)

CMS

This is the database which integrates management of all information and data on construction turnover systems, and also which are linked and synchronized with the engineering and procurement systems. This system has the function of simulating the work front based on the status of documents/materials/predecessor -, schedule, constraints and priority of construction and handover. The system is the infrastructure of our construction risk management system, which is one of our strengths.

Origin®

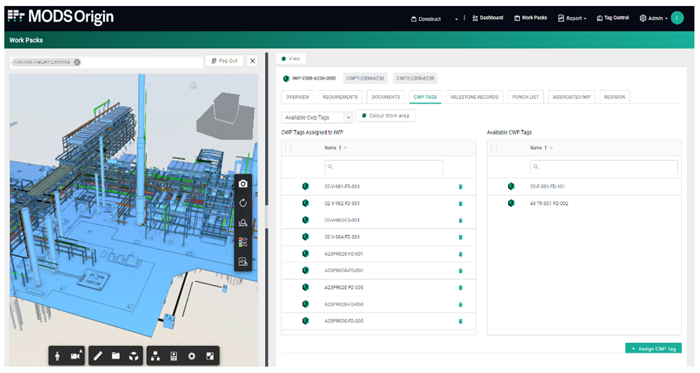

A group of applications with 3D collaboration and paperless functions, named as Origin®,has been jointly developed with MODS. These applications enable us to manage key construction and handover works with paperless such as IWP planning, piping testing, instrumentation loop testing, inspections and construction permits. Also it provides powerful support for sharing real-time information and decision-making among stakeholders through 4D visualization. (See Figure 1)

FieldOpt®

A group of systems that manages construction resources such as people, construction equipment and materials. These systems enable us to monitor labor working and operational status for effective productivity management, by combining software and hardware such as RFID, GPS, and Beacon.

Figure 1: Origin® - Jointly Developed with MODS

Figure 2: Construction and Turnover Management Overview

Procurement and Project Management

PMS

The Procurement and Project Management System (PMS) consists of document management system, material take off & control system, purchase order system, expediting control system and logistics control system. These systems enable to liaise seamless information among engineering, construction and vendors.

Integrated Correspondence and Ticket System (Corret)

Corret is an integrated communication platform that realizes effective and smooth communication with all stakeholders involved in EPC projects. This system enables to manage and to share effectively all communications and actions such as letters, work tickets and minutes of meeting among inter-company, inter-department, and inter-personnel.

Our Strengths

As a project size becomes getting larger, the number of items and activities which need to be managed becomes getting enormous accordingly. With such trends, the relationships on project execution also become getting extremely complex. If the project status cannot be grasped due to increased complexity, problems will arise and go unnoticed, resulting in schedule delays and cost overruns.

As mentioned above, JGC has in-house systems that realizes Project Digital Twin which incorporates concept of AWP and Data Centric EPC . JGC contributes to solve a variety of difficult, complicated issues by delivering reliable project execution management which combines with our unique strength.