Construction of Fossil Energy Plants with a Lighter Environmental Footprint

LNG Plant Construction

In view of energy demand from a growing global population, fossil fuels are expected to continue to fulfill an essential role to a certain extent over the next few decades.

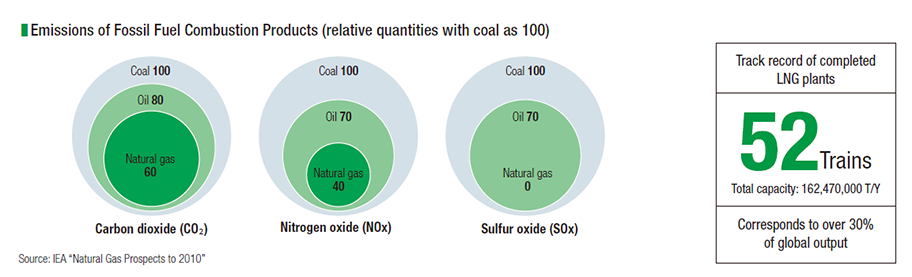

Among fossil fuels, natural gas has a low volume of carbon dioxide (CO2) and nitrogen oxide (NOx) compared to coal and oil when burned, and its use is being expanded globally as a source of energy with an extremely low environmental burden that emits no sulfur oxide.

JGC possesses the technology to design and construct liquefaction equipment, the heart of LNG plants-something that few companies in the world are able to do. Since building JGC's first LNG plant in Brunei in 1973, over a period of 50 years we have designed and constructed LNG plants responsible for over 30% of global output, responding to our clients' needs and accomplishing their projects as the leading contractor of LNG plants.

Furthermore, in recent years we have been developing technology for offshore LNG plants constructing and improving the productivity of LNG plants using AI technology, and we are actively working towards creating an environmentally friendly society through our business activities.

Dry Desulfurization and Denitration Technologies

Development of Dry-type SOx and NOx Removal System for Mid- and Low-temperature Flue Gases

JGC has combined the dry denitration technologies of Group company JGC Catalysts and Chemicals Ltd. (JGC C&C) with the dry desulfurization technologies of a partner company in Japan to create the world's first dry-type SOx and NOx removal system for mid- and low-temperature flue gases. JGC and local partners are providing and installing this system in China, where the government is tightening emission regulations to address the growing problem of atmospheric pollution caused by gas emissions.

With atmospheric pollution from gas emissions now an increasingly serious issue in other countries across Asia, JGC plans to roll out the system in India and other markets in the region.