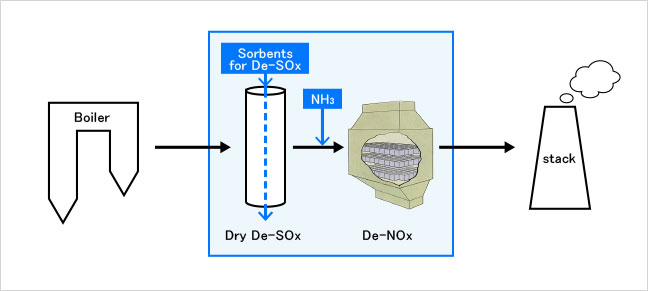

Dry De-SOx/De-NOx System

Dry De-SOx/De-NOx system removes SOx, NOx, and dust from flue gas.

The Dry De-SOx/De-NOx system has been developed by integrating JGC group's De-NOx technology and Hokkaido Electric Power's dry De-SOx technology. The system has achieved a high SOx and NOx removal rate of more than 90% and has a proven track record at a combustion exhaust gas treatment facility for coke ovens in China.

Features

- Apply to a wide range of temperatures from 100 ℃ to 400 ℃

- High efficiency removal rate of 90 % or more of NOx and SOx

- High efficiency removal rate of 85 % or more of dust

- A little decline in flue gas temperature, and gas reheating is not required

- No waste water treatment required

Applications

- Flue gas of Coal-fired power

- Flue gas from coke oven gas conversion

- Flue gas of incineration plant

- Flue gas of cement kiln

- Flue gas of industrial boiler

Dry De-SOx/De-NOx System

Experience

- De-SOx/De-NOx system for flue gas from coke oven gas conversion: 80 units

Energy Transition - O&M/Other Services

- Consulting Service for Reliable Plant Maintenance

- Highly Efficient Post Weld Heat Treatment (PWHT) Technology

- Materials Selection for Plant Facilities

- Improvement of Maintenance Strategy to Corrosion Damages; Investigation of the Root Causes and Countermeasures

- Flow Simulation Technology

- Dry De-SOx/De-NOx System