Highly Efficient Post Weld Heat Treatment (PWHT) Technology

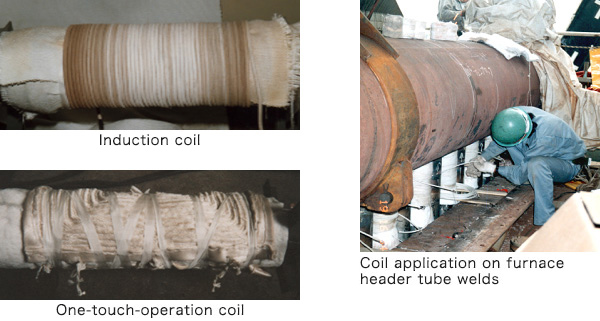

Piping installation involves tens of thousands of PWHT points in a large plant, and dozens to hundreds of points even in a small maintenance project-a fact that means the impact of PWHT on a piping construction schedule can be considerable. This highly efficient PWHT technology using induction heating is a time saving technique that enables a far higher heat-up rate (1,000 degrees C/Hr) than conventional PWHT with an electric resistance heating element.

Features

| Heat-up Method | Rate (degree C/hr) |

Efficiencies |

|---|---|---|

| Conventional electric resistance heating | 200 | 1 step/night |

| Induction heating | More than 1,000 | 2 steps/night |

- Wide and uniform heated zone

Wide enough to cover ASME-specified uniform heated zone at PWHT - Highly accurate temperature control

Inverter-controlled power source enables accurate heat-up/hold/cool-down steps - High level of safety

Differ from annealing with an electric resistance heating element, a non-heat-generating induction coil assures a high level of safety - Easy installation

One-touch-operation coil (a built-in coil sheet to be placed around piping) enables simple fixing and removal as compared with induction coil winding around piping

Applications

- Piping construction in general, furnace tubes

Experience

| Plant/Piping | Materials | No. of Joints |

|---|---|---|

| Amine Plant | Carbon Steel | 200 |

| Gas Plant | Carbon Steel | 800 |

| CCR Plat. | 9Cr-1Mo+Incoloy800 | 250 |

| HDS/CCR | Carbon Steel,9Cr-1Mo | 800 |

| CCR Plat. | 1-1/4Cr-1/2Mo | 50 |

| CCR Plat. | 9Cr-1Mo | 500 |

| Gas Plant | Carbon Steel | 160 |

| Gas Plant | Carbon Steel | 850 |

Energy Transition - O&M/Other Services

- Consulting Service for Reliable Plant Maintenance

- Highly Efficient Post Weld Heat Treatment (PWHT) Technology

- Materials Selection for Plant Facilities

- Improvement of Maintenance Strategy to Corrosion Damages; Investigation of the Root Causes and Countermeasures

- Flow Simulation Technology

- Dry De-SOx/De-NOx System