HiPACT® - an Innovative CO2 Capture Process

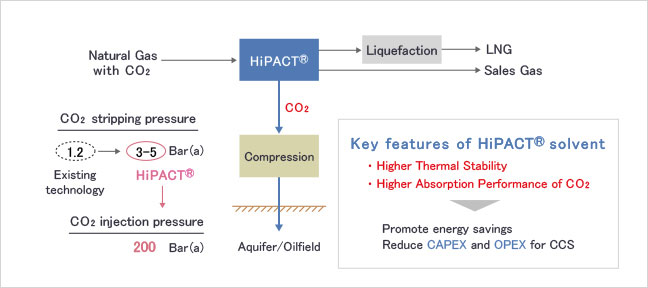

HiPACT® recovers CO2 at high pressures from natural gas and synthesis gas, enabling cost reduction and energy saving in carbon dioxide capture and storage (CCS). HiPACT® has been jointly developed with BASF SE.

A demonstration test has been successfully completed at INPEX’s natural gas plant in japan and the technology is at the marketing stage. In 2015, NIS a.d. Navi Sad, a Serbian oil company, started commercial operation of a gas processing and CCS facility with CO2 capture applying HiPACT® process, and has been operating successfully.

Further, HiPACT® has been adopted in the "Kashiwazaki Clean Hydrogen/Ammonia Project" in Japan to be implemented by INPEX as part of the New Energy and Industrial Technology Development Organization (NEDO) subsidized project "Technology Development for the Utilization and Production of Ammonia as Fuel / Technology development for Blue Ammonia production". The plant is scheduled to start operation in 2025.

The introduction of HiPACT® is also underway for clean energy production plants such as for hydrogen and ammonia, which are becoming increasingly important in the bid to achieve carbon neutrality.

Features

- A chemical absorption process, using a newly developed absorption solvent;

- Highly stable against thermal degradation

- Superior CO2 absorption performance

- Enabling CO2 stripping process at high pressures simultaneously with energy saving, which significantly reduces the energy and cost loads of CCS projects

- Enabling a reduction of 25 to 35 percent in CO2 recovery and compression costs

- Beneficial to not only CCS but also to CO2-EOR (Enhanced Oil Recovery) and pure CO2 production for e.g. liquefied CO2 or further processing to chemicals

Applications

- CO2 capture sections in

- natural gas processing plants including LNG plants

- synthesis gas (syngas) processing plants to synthesize chemical products e.g.

ammonia, urea, hydrogen, acetic acid, methanol and substitute natural gas (SNG) - IGCC (Integrated Gasification and Combined Cycle) plants, especially those

based on coal and heavy oils

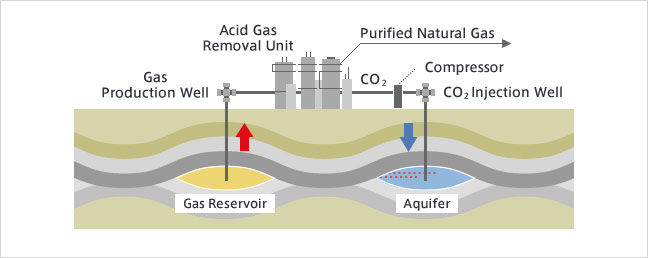

Illustration of CO2 Capture and Storage Scheme

Experience

NIS a.d. Novi Sad (Serbia)

- Natural gas processing with CCS (Europe), 1 License

- Blue hydrogen and ammonia production with CCS (Japan), 1 License