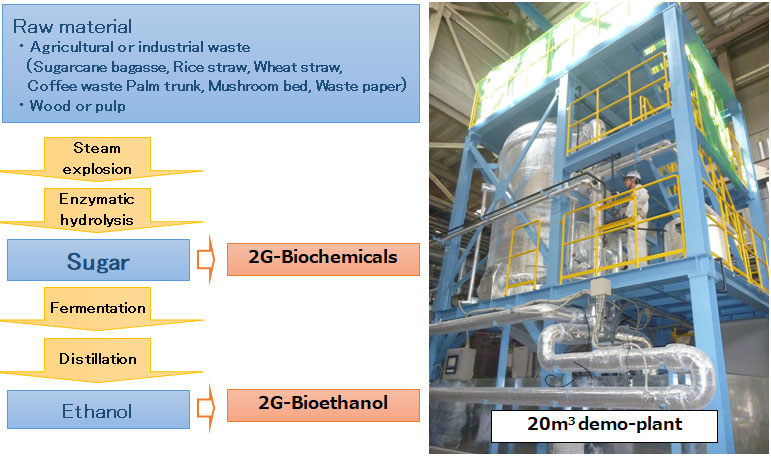

2nd Generation Bioethanol Production Process

This is a "2G (second generation)-bioethanol" process using inedible resources as raw materials. This process does not compete for food resources and leads to reduced CO2 emissions. "2G-sugar" which is an intermediate in this process, can be used as a material for bio-based chemicals.

2nd Generation Bioethanol Production Process

Features

- Inedible resources can be used as raw material.

- Enzymatic hydrolysis can be carried out under the high viscosity condition.

- Unique hydrolysis process allows for enzyme usage reduction.

Applications

- Raw materials

- Agricultural or industrial waste (Sugarcane bagasse, Rice straw, Wheat straw, Coffee waste, Palm trunk, Mushroom bed, Waste paper)

- Wood or pulp

- Products

- 2G-Ethanol

- 2G-Sugar (for bio-based chemicals)

Development Status

- Demonstrated at 20 m3-scale

- Viable projects for commercial use for domestic and overseas clients are being investigated