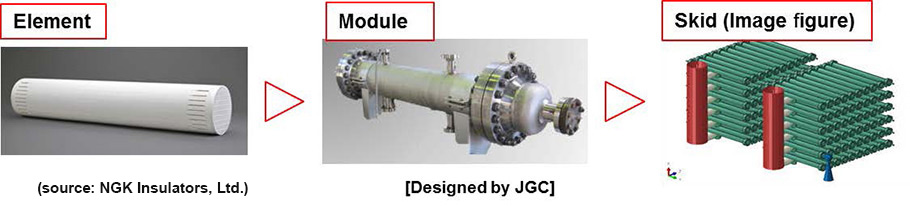

DDR Membrane - CO2 Separation for Natural Gas Treatment

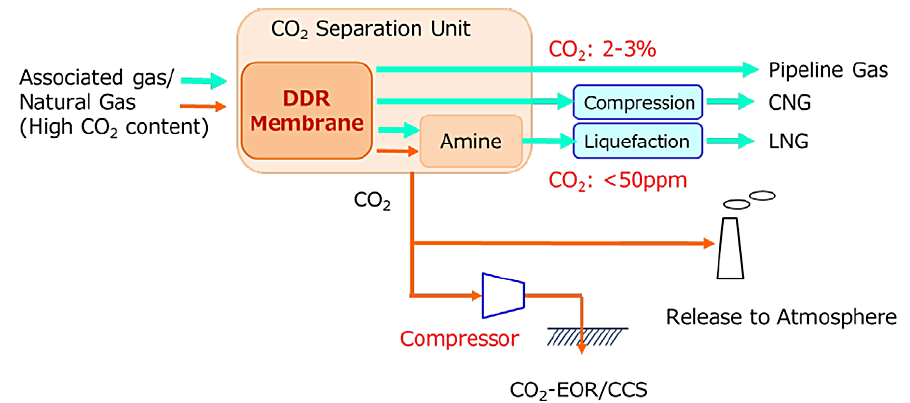

DDR membrane process is a high-efficiency CO2 separation technology using a DDR-type zeolite membrane. It is suitable for CO2 separation from associated gas deriving from CO2-EOR and natural gas with high CO2 content. DDR membrane can enhance product yields because of a very high selectivity for CO2/CH4. This technology is jointly developed by JGC and NGK Insulators, Ltd.

Advantages of DDR Membrane

- Applicable to high pressure and high CO2 gas fields (high CO2 partial pressure durability)

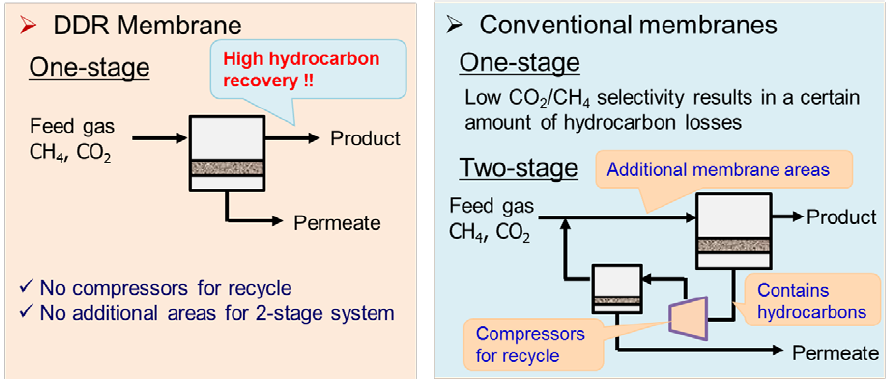

- CH4 loss in DDR membrane process is much smaller than in conventional polymeric membrane process

(Approximately 1/10 or less than conventional polymeric membranes) - DDR membrane enables an economic, one-stage system

- DDR membrane can be adapted to changing, increasing levels of CO2 over time, by retrofitting

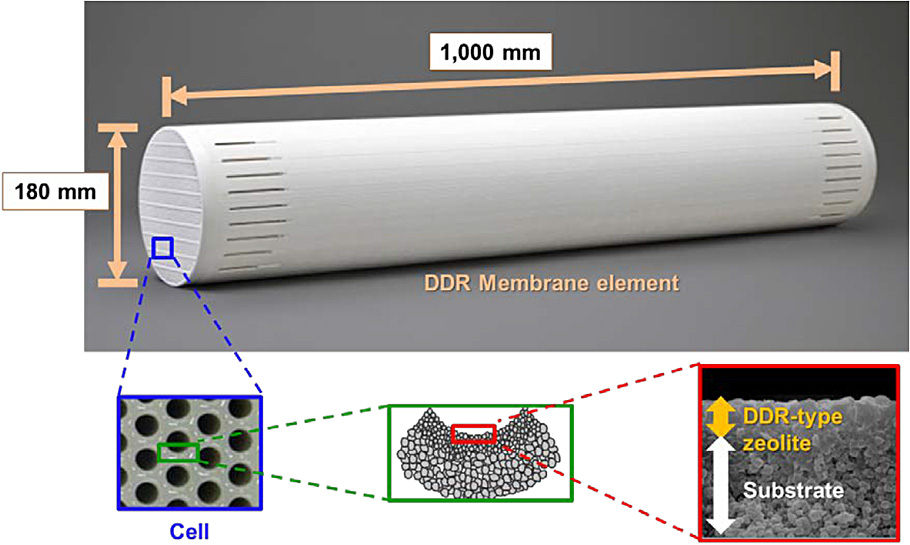

- The largest zeolite membrane element in the world, it can only be manufactured by NGK Insulators, Ltd.

DDR Membrane Element

| Element size | Diameter: 180 mm, Length: 1,000 mm |

|---|---|

| Membrane surface area | 12 m2 |

| Membrane module type | Monolithic |

| Pressure resistance | Max. 8 MPaG |

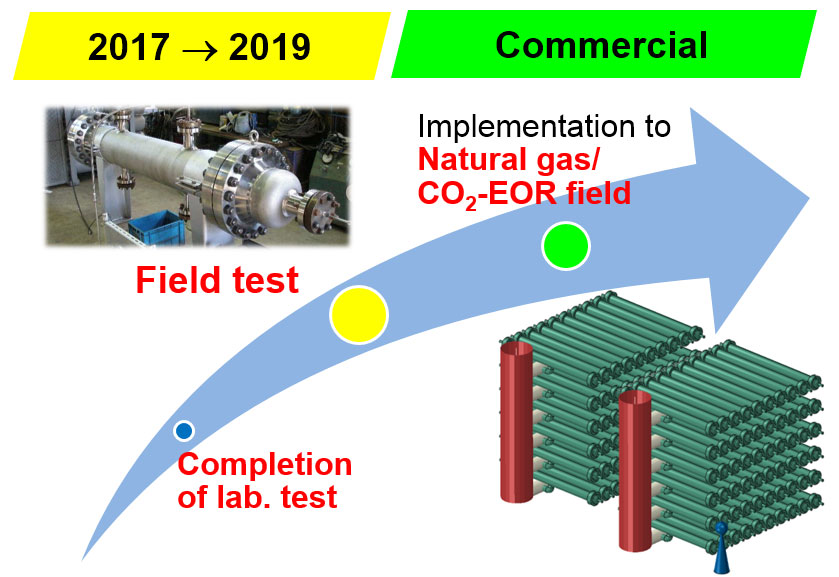

Road Map to Commercialization

Current stage is field test stage. After completion of field test, DDR Membrane will be commercialized.