Examples of Usage of IP and Intangible Assets

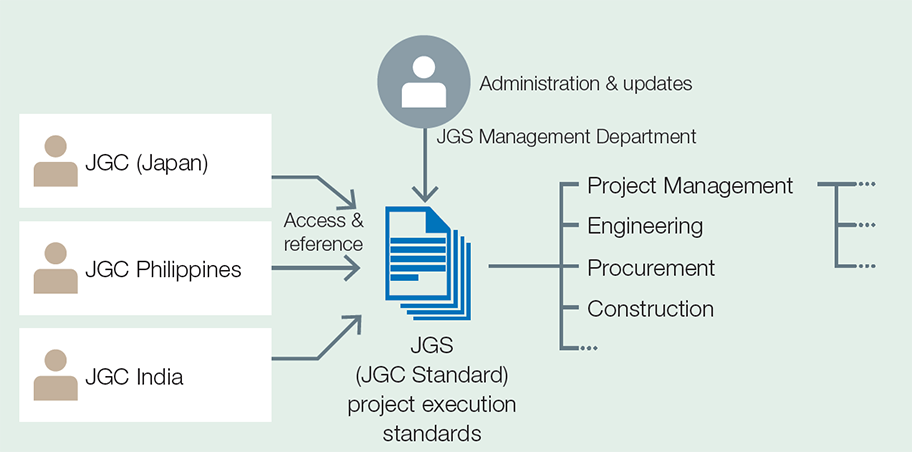

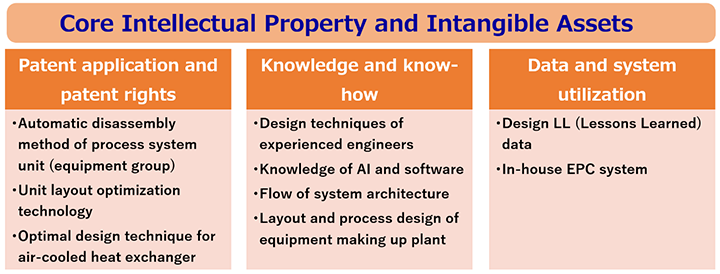

Standardization of EPC project execution know-how that the Group has accumulated over the years, and promotion of quality improvements in EPC project execution

The Group has accumulated a wealth of knowledge and know-how related to project execution over many years’ experience with numerous EPC projects.

In recent years, projects have tended toward being larger and more complex. In our transformation of EPC operations, there is a need for further improvements in project execution capabilities and quality. In achieving this, the Group considers the knowledge and know-how related to project execution that has been collected so far as a source of competitive advantage, and is organizing this as organizational and explicit knowledge. This extracted knowledge and know-how is standardized and systematized as the JGC Standard (JGS), and is utilized by each Group company including overseas subsidiaries when executing projects.

The JGS comprises over 1,000 standard documents, categorized by field and depth. The dedicated department for managing the JGS regularly adds new items and revises existing ones, thus ensuring that the JGS is kept current with the knowledge and know-how gained from new projects. The standardization of project execution using the JGS plays an important role as the foundation upon which the Group can expand our EPC business globally.

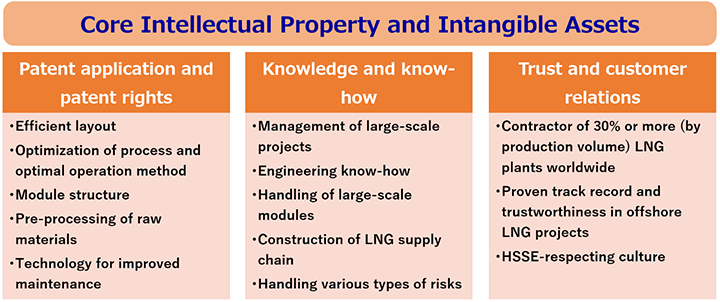

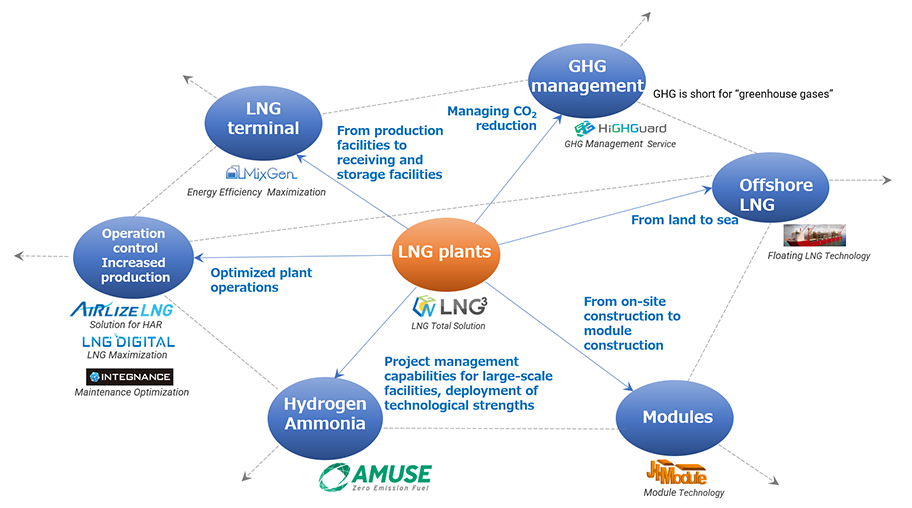

Provision of Multidiscipline Engineering in LNG Production Facilities

The JGC group, which has been a leading company in building liquified natural gas (LNG) production plants, has been involved in building projects for 30% or more of all LNG production plants worldwide, utilizing experience spanning around half a century, and expertise. Also, we are providing solutions that maximize the value of LNG plants, out of various LNG-related technology that our group has, in each phase of the life cycle, such as EPC support of customer's "LNG businesses", new design plans, stable plant operation, and further increased LNG production and reduction of greenhouse gasses by energy conservation through effective investment. Knowledge and know-how cultivated through providing various solutions, and intellectually property rights are being put to use to expand into various businesses and technologies, such as offshore facilities, module building method, operation control of plants, making entire value chains low-carbon/carbon-free, and so forth.

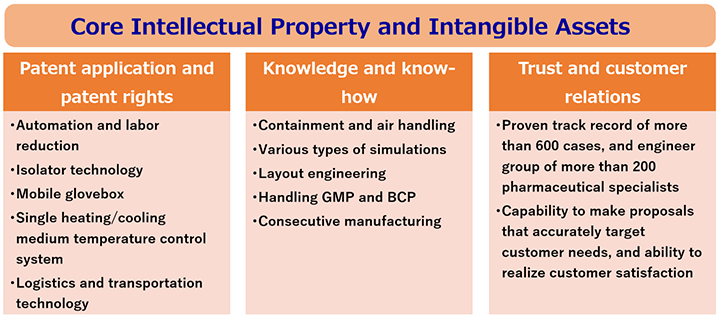

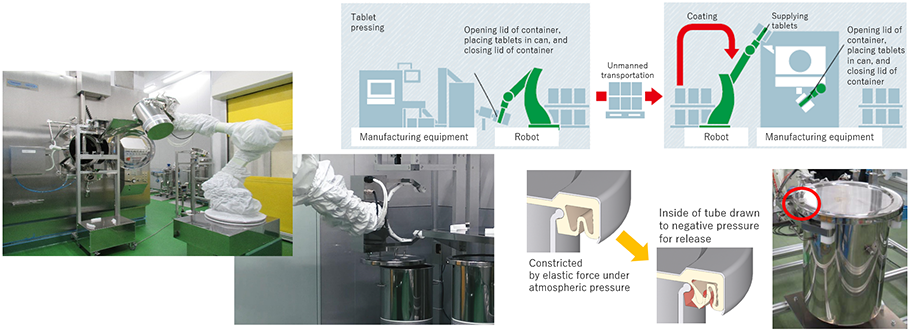

Innovation in Pharmaceutical-Related Facilities

The JGC group holds healthcare and life sciences as one of its main businesses, and is proceeding with measures to handle global population increase and aging societies, and to realize high medical standards. We entered the field of building pharmaceuticals manufacturing facilities and installations in the 1980's, and our strengths are a rich performance history, proposal abilities that meet strict facility demands, and flexible ideas that combine various technologies.

In recent years, there is increased customer demand for worker safety in various types of production facilities, cost-saving, and so forth. Our group grasps such customer issues early on, and having been involved in building solid preparation plants for many years, invented a simple container lid opening/closing mechanism "BLATTM", to automate processes relating to opening and closing containers while ensuring airtightness of the containers. As a result, reduction in the size of containers, and reduction of workers have been realized at the same time. One robot is capable of all small-can handling including opening and closing operations, with the advantages of reduced costs and reduced maintenance work. In addition, the risk of contamination of the preparation by foreign matter can be reduced. There is no supply of raw materials from above, and accordingly there is no ascending and descending of stairs by employees. Accordingly, a plant with extremely high safety for both products and employees can now be provided.

Application is not limited to pharmaceuticals, and fields of application are spreading to food, cosmetics, and chemical products and so forth as well.

- *"BLATTM" was developed in joint with Mutsubishi Rubber, Co., Ltd. (Awarded the Invention Encouragement Prize in the 2022 Kinki Regional Commendation for Invention)

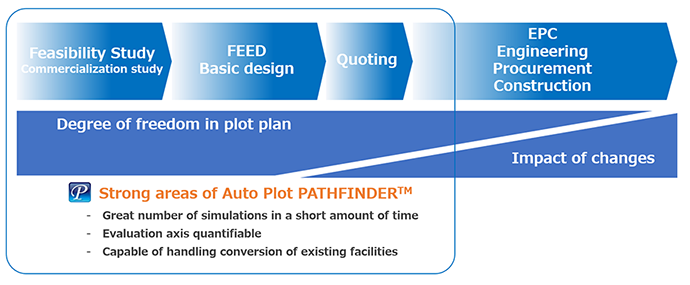

Design innovation through Auto Plot PATHFINDER® DX

The plot plan is the overall layout of the plant, and its design requires advanced technology in order to optimize various requirements while being subject to complex constraints. As such, this field has been heavily reliant on the intuition of experienced senior engineers. The Auto Plot PATHFINDER® automated plot plan design system utilizes three technologies to automate and optimize plot plan design. These are: (1) division of process flow units through the use of graph clustering*; (2) automation of equipment layout within units by formalizing and codifying the tacit knowledge of senior engineers; and (3) automatic optimal placement of units through the use of genetic algorithms.

Our Group actively utilizes Auto Plot PATHFINDER® in plot plan design tasks for FS and FEED. By protecting our design automation technology with IP rights, the Group will secure the improved efficiency of plot plan design and new proposal-based design (Generative Design) as the basis of our Group’s competitive advantage, with which the Group will strive to create and expand business opportunities in the construction of a variety of plants.

- ※A technology for clustering and analyzing large-scale data that has been graphically structured to represent complex connections, based on data attributes

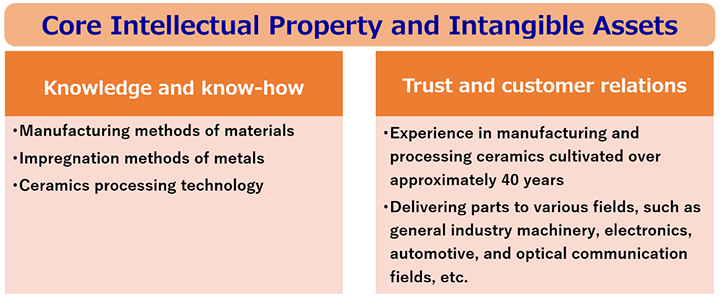

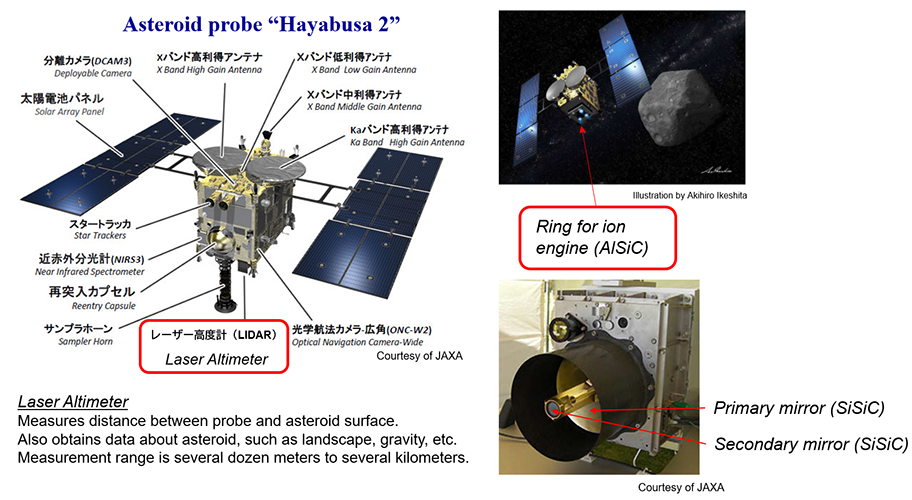

Expansion of Application for Metal-Ceramics Composite Material "MMC"

MMC (Metal Matrix Composites), developed by Japan Fine Ceramics Co., Ltd. of our group, is a composite material of metal and ceramics. It is used in a wide range of applications, such as stage components for semiconductor and LCD (Liquid Crystal Display) manufacturing equipment and guide components for inspection equipment because of its lightweight, high rigidity, excellent thermal dissipation, and low thermal contraction. It was adopted as a component of the asteroid probe "Hayabusa2" in recognition of its highly functional characteristics that enable precise design.

In addition to MMC, we also focus on the development of applications that take advantage of the characteristics of various ceramic products such as engineering ceramics and electronic ceramics.

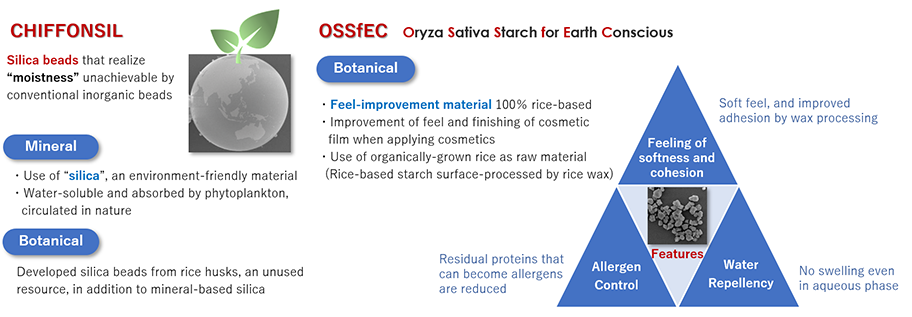

Development of Substitute Materials that Contribute to Reduction in Amount of Microplastic Beads Washed out to Sea

In recent years, there is concern that minute pieces of plastic called microplastic that have accumulated in the oceans and lakes over long periods of time will adversely affect the environment, including the ecosystem. One type of microplastic is a fine-grained feel-improvement material (microplastic beads (MPB)) for cosmetics, and is used as a cosmetic raw material. However, in recent years, restricting use thereof is being studied in many countries and regions, and application of a substitute material is awaited. Amidst such increasing demand, JGC Catalysts and Chemicals Ltd. of our group has fallen in line with "Clean Beauty" that cosmetic users worldwide aim for, and further used their nanomaterial control technology and developed a silica beads product "CHIFFONSIL" that is a mineral and botanical material, and "OSSfEC" that is rice-based starch particles, to serve as substitutes for microplastics, to protect our irreplaceable planetary environment. A proposal was made to a customer cosmetics manufacturer, and was employed.

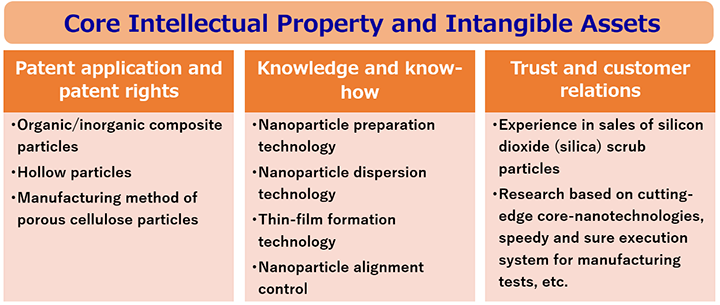

JGC Group's Approach to IP and Intangible Assets

- JGC Group's View on IP and Intangible Assets

- Building a Strategic IP Portfolio

- Efforts in Co-Creation

- Implementation System of IP Strategies Linked to Business and Development Strategies

- Strategic Usage of IP and Intangible Assets

- Risk Management for IP and Intangible Assets

- Educational Programs on IP

- Examples of Usage of IP and Intangible Assets