News Releases 2019

Feb. 25, 2019

Start of the Demonstration Test of the CO2 Recovery Process Using DDR-Type Zeolite Membranes

Yokohama, Japan - JGC Corporation has announced the start of a joint demonstration test (hereinafter "the Test") with Japan Oil, Gas and Metals National Corporation (hereinafter "JOGMEC") on CO2 recovery using zeolite membranes from February 1, 2019.

In the Test, the CO2 recovery process (hereinafter "the Process") using the DDR-type zeolite membrane(*1) jointly developed by NGK INSULATORS, LTD. (hereinafter "NGK") and JGC will be used for the first time in the world to recover CO2 from associated gas.

The details are as follows:

- (*1) Zeolite is a microporous crystalline aluminosilicate. Many varieties of zeolite are currently being synthesized artificially and used industrially as a catalyst, adsorbent, etc. DDR is one of zeolite's framework structures.

1.Overview of the Test

| Name: | Field demonstration test of DDR-type zeolite membrane technology |

|---|---|

| Demonstrator: | Joint project by JOGMEC and JGC |

|

Site: |

Texas, U.S. |

|

Targeted gas: |

Associated gas generated during oil production |

|

Details: |

Optimization and performance test on a CO2 recovery facility using DDR-type zeolite membranes (associated gas processing capacity: 3 million cubic feet per day) |

| Future plans: | Designing and construction of the test facility began in February 2019, and demonstration tests will be carried out over approximately one year after its completion |

2.The Aim of the Test

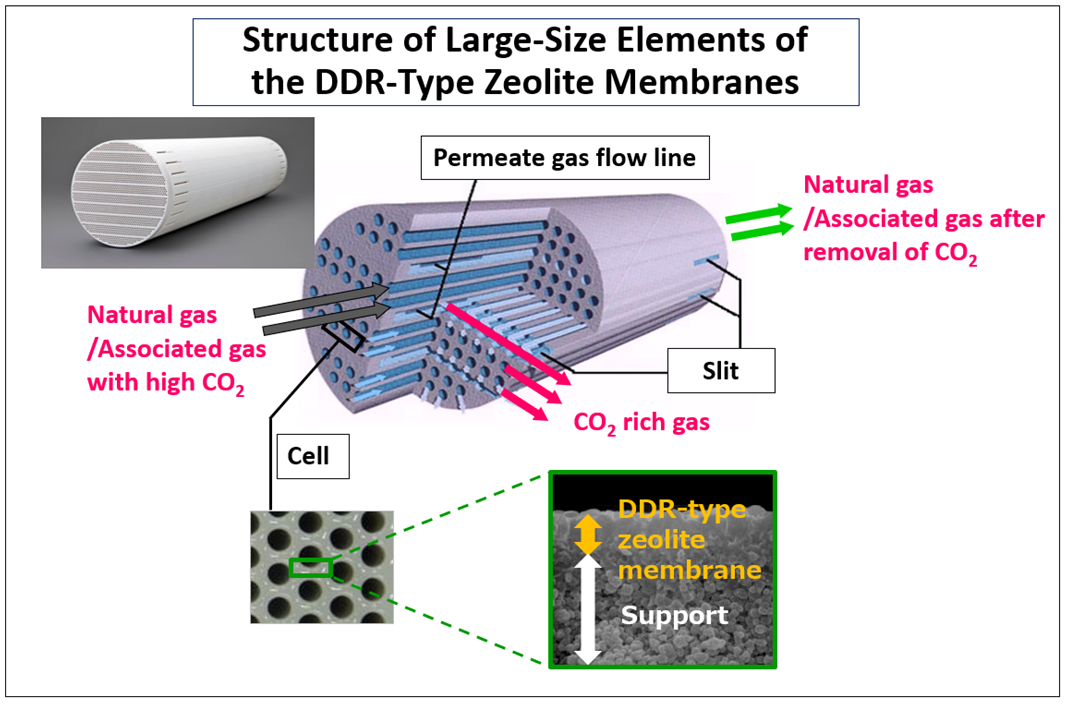

The Test will confirm the performance of the Process using large-size elements (180 mm diameter × 1,000 mm length) of the DDR-type zeolite membrane, and in doing so, aims to verify their effectiveness for various purposes of use described below.

The Process has been jointly developed by NGK and JGC since 2008. The DDR-type zeolite membranes used in the Process has been developed and will be manufactured by NGK using their advanced membrane production technology, and their outstanding CO2 selectivity and high pressure resistance have been verified in tests carried out at the research facility.

3. Application of the Process and Current Issues

JGC expects the Process to be applied for the two purposes of CO2 recovery from associated gas during oil production, and CO2 removal during natural gas processing. Current methods generally rely on the use of the polymer membrane process for the former, and the chemical absorption process for the latter, but in processing gases containing high concentrations of CO2, the following have been recognized as being issues:

1)CO2 recovery from associated gas during oil production

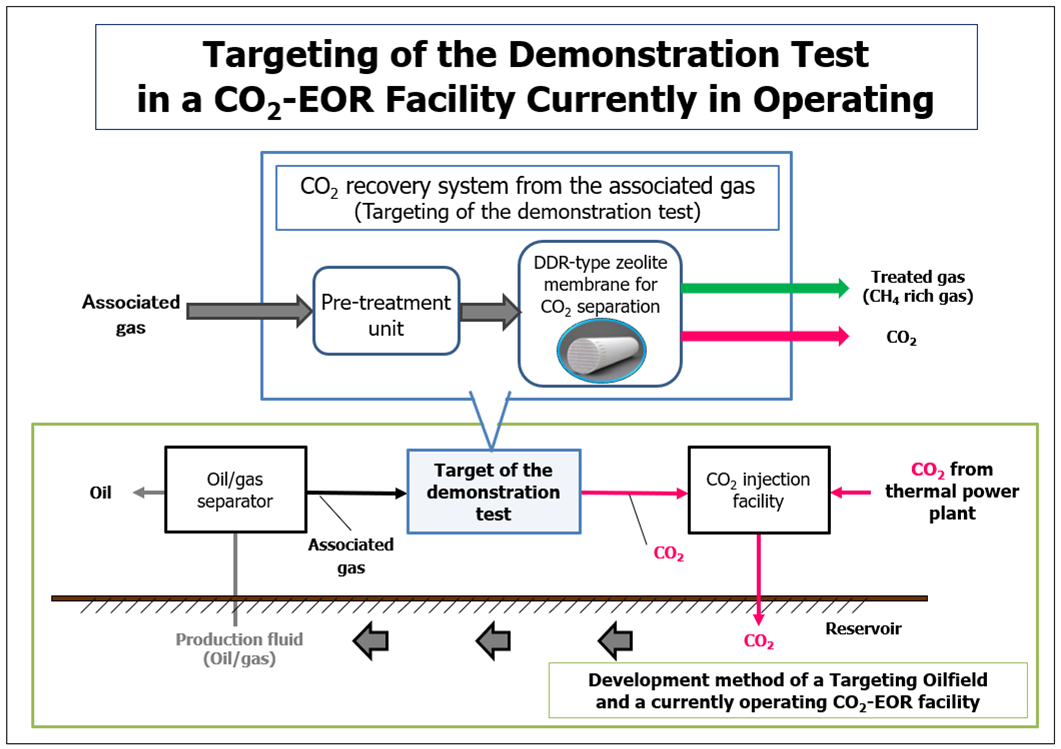

In CO2-EOR(*2), which is one of the prime examples of CCUS(*3), CO2 is separated and recovered from associated gas during oil production and reused. The polymer membrane process is generally used in this method of CO2 separation, which is energy-efficient and requires little initial investment. However, the significant deterioration of polymer membranes often occurs when the associated gas contains high concentrations of CO2. This causes a problem because the membrane replacement cost increases.

On the other hand, the DDR-type zeolite membrane is highly durable even under high CO2 concentration conditions. It is expected that applying the Process will reduce the operational cost of recovering CO2 from associated gas, and contribute to the promotion of CO2-EOR.

- (*2) CO2-EOR; CO2 Enhanced Oil Recovery

Technology in which CO2 is injected into the oil reservoir to lower the viscosity of the crude oil, improve its fluidity, and boost the oil production. During this process, it is known that a part of the injected CO2 is stored underground, and not emitted into the atmosphere.

-

(*3) CCUS(Carbon dioxide Capture, Utilization and Storage)

Initiatives to create economic value through the recovery and storage of CO2, as well as its effective use as measures against global warming, which have been attracting attention from around the world in recent years.

2)CO2 removal during natural gas processing

In the chemical absorption process, the amount of solvent required increases as the concentration of CO2 in natural gas rises, leading to an increase in the energy required for solvent regeneration. This leads to an increase in the cost of CO2 removal, which is a problem in the development of gas fields with high concentrations of CO2.

JGC is deploying the Process for bulk CO2 removal with less energy consumption, prior to the chemical absorption process to lower the cost of gas processing. JGC believes this technique can be used for the development of gas fields with high concentrations of CO2, where little development had been made until now.

4. The Social Value of CO2-EOR Promotion and Natural Gas Development

With increasing populations and rising standards of living in developing countries, the global demand for energy has continued to expand. Proactive initiatives are currently being implemented to boost the efficiency of energy use and expand the use of renewable energy, but it is believed that fossil fuels will continue to play an important role over the next several decades. Under these circumstances, it is believed that the development of the Process will contribute to increased oil production and the underground storage of the greenhouse gas, CO2, as well as the expanded use of natural gas, which has a relatively low environmental impact among fossil fuels. This will be of huge social value by achieving both the expansion of the energy supply and measures against global warming.

In addition to the U.S. where CO2-EOR has been implemented since the 1970s, its expanded deployment has been considered in recent years in various countries in Southeast Asia and the Middle East. Moreover, there are numerous gas fields with high concentrations of CO2 in the Southeast Asia region, including Malaysia and Indonesia, where there is a possibility that progress will be made in the development of these gas fields due to the economic feasibility of the Process in primary treatment to remove CO2.

Through the practical application and active promotion of this CO2 recovery process, making use of DDR-type zeolite membranes, JGC hopes to contribute to the expansion of CCUS, and promote the use of natural gas and LNG (Liquefied Natural Gas).