News Releases 2018

Aug. 06, 2018

JGC and PETRONAS Collaborate to Improve Efficiency of Existing LNG Plants Using AI and IoT

Yokohama Japan - JGC Corporation has announced today an agreement with PETRONAS Research Sdn Bhd, a wholly-owned subsidiary of the Malaysian state-owned oil company Petroliam Nasional Berhad (PETRONAS), to collaborate on improving the operational efficiency of existing Air-cooled LNG plants* by using Artificial Intelligence (AI) and Internet of Things (IoT) technologies. This collaboration will be conducted under the Heads of Agreement (HOA) between both companies signed in July 2018 to jointly develop systems and conduct demonstration tests to increase LNG production by predicting Hot Air Recirculation (HAR), a key challenge when operating Air-cooled LNG plants.

PETRONAS possesses a wealth of experience and data accumulated through its numerous oil and natural gas-related facilities across the world. This collaboration will combine the strength of PETRONAS with JGC's extensive track record and excellent technological capabilities in the LNG field, and is expected to provide a highly efficient plant operating service. The two companies currently plan to design a system for increased LNG production and make progress with the demonstration testing needed to install this system into PETRONAS-owned LNG plants in Malaysia.

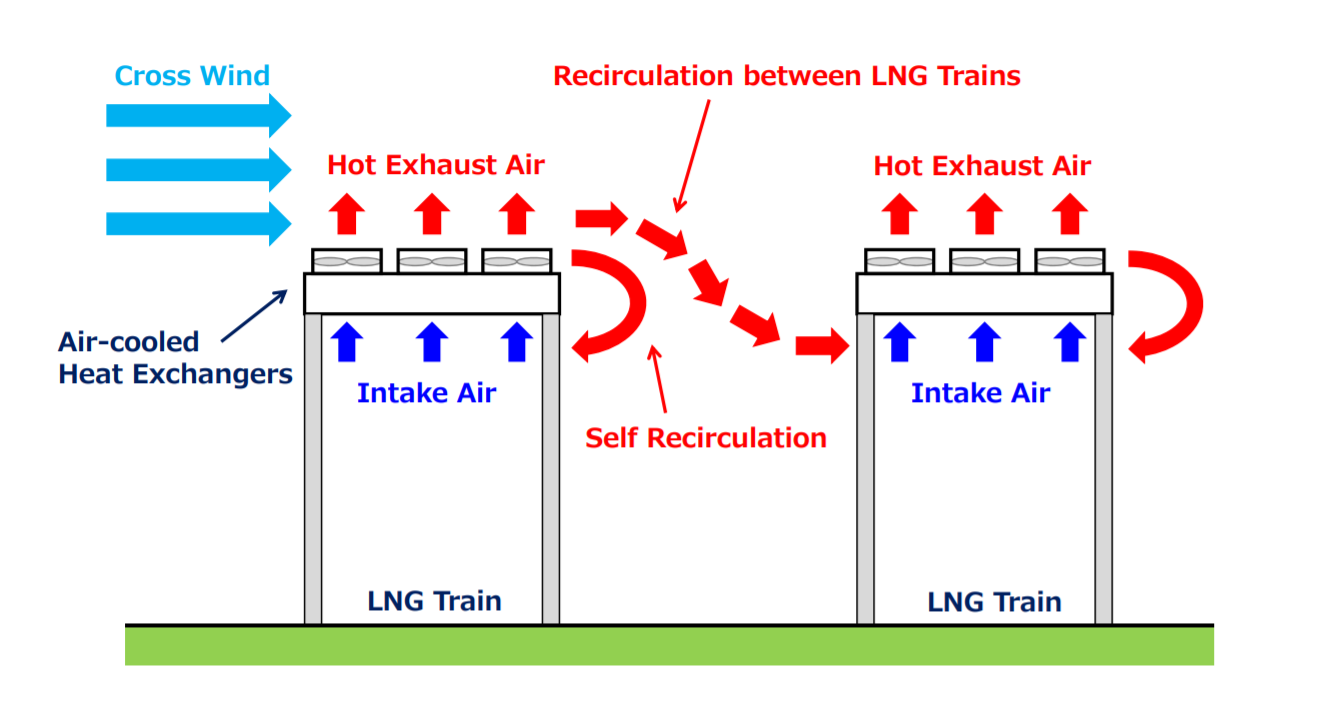

In Air-cooled LNG plants, hot exhaust from air-cooled heat exchangers located within the plant is drawn into the air intake, reducing cooling capacity. This phenomenon known as HAR constantly challenges the requisites for highly efficient plant operations and impairs the potential to further increase production.

JGC established an investigation team in 2008 to resolve HAR and achieve steady and efficient LNG plant operations. AIRLIZE LNG® service has since been provided for the design and build of optimal plants as well as the locating of equipment to control the air and minimize the impact of HAR. To date, the service has been deployed in more than 10 overseas projects.

This collaboration leverages AIRLIZE LNG® and HAR occurrence prediction by integrating AI and IoT into the advanced Computational Fluid Dynamics (CFD) and operation based simulation technology for existing LNG plants operations. Both parties intend to engage all existing plants having HAR concerns, whilst proposing a similar approach as a key technical differentiator in planning new LNG plants.

* Air-cooled LNG plant

Many LNG plants constructed between the 1960s and 1980s used seawater to chill the refrigerant in the heat exchanger when liquefying natural gas. However, numerous LNG plants designed and constructed since the late 1980s have adopted air cooling in order to accommodate the needs of minimizing the impact to the environment due to warm water discharge.

<Attachment>

Hot Air Recirculation(HAR) Mechanism