Logistics Planning Technology

Realizing High-quality, High-efficiency Factories with Optimal Logistics Planning

In pharmaceutical factories, logistics and automatic transportation are an effective means to prevent confusion even outside of manpower saving. By applying optimal logistics facilities, JGC realizes high-quality, high efficiency factories.

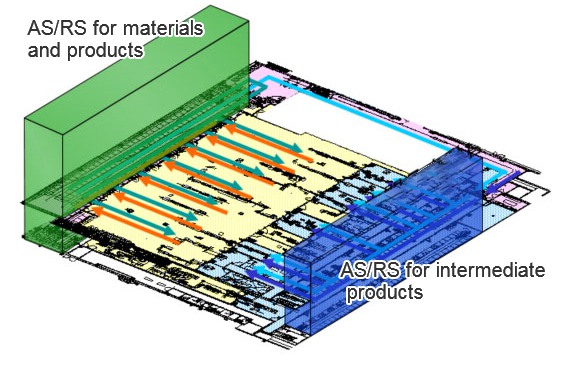

STACKER FLOW®

JGC is the pioneer for STACKER FLOW® by applying for the first time in Japan stacker cranes used in AS/RS for dedicated IBC transportation use in solid dosage factories. By using the stacker cranes, we have made intermediate product supply at any height and automatic storage possible.

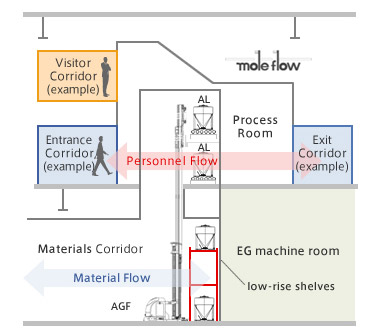

MOLE FLOW®

By dividing the production facility floor and the logistics floor vertically using Automated Guided Forklifts (AGF), JGC realizes a "people-friendly factory" that reduces employees' vertical motion. AGF are easy to introduce because they are battery-powered, and adopting multiple AGF enables them to exhibit their power in terms of stable factory production (BCP) (Patented).

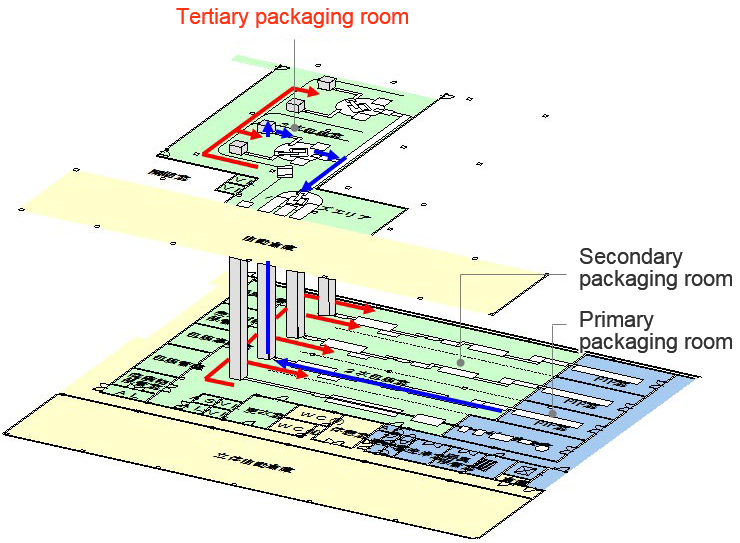

Automatic Transfer of Packaging

In packaging, there are many packaging material transportation flows including intermediate products. In order to prevent confusion, JGC proposes transportation to eliminate crossing of flow lines as much as possible.

Healthcare & Life Sciences

- Sterile Pharmaceutical Manufacturing Support Technology

- Single-Use Technology

- Design Technology for Active Ingredient Pharmaceutical Plants

- Logistics Planning Technology

- Containment Engineering

- Cell Culture Technology

- GMP Compliance Technology

- Continuous Manufacturing

- Layout Engineering

- Pharmaceutical Module Engineering

- Energy Saving/Environmental Technology

- Business Continuity Planning Technology

- Technologies of Swing and Nikki-Universal