High-Throughput and High-Efficiency Extraction Column (WINTRAY®)

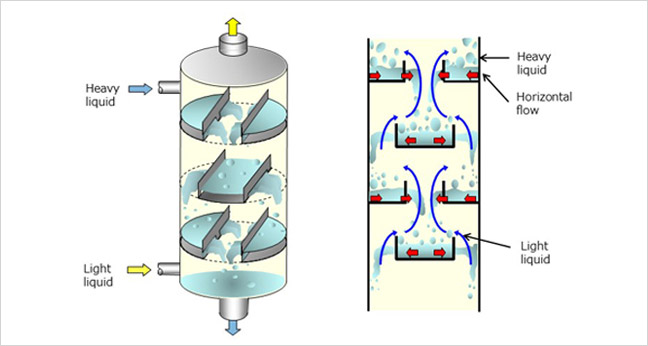

The WINTRAY® liquid-liquid extraction column offers high throughput and high efficiency at a low cost, and can be used for extraction of organic compounds, inorganic compounds, and non-ferrous metals, as well as reactive extraction. This extraction column alternately combines two types of trays (WINTRAY®) with vertical plates and openings to discharge the heavy liquid accumulated above the trays (in the figure below, the dispersed liquid is heavy liquid) from the opening in the form of a liquid sheet, producing dispersion droplets. The produced dispersion droplets are larger than those formed in conventional extraction columns. The liquid sheet repeats deformation motion until all the liquid is dispersed, stimulating mass transfer. As a result, this extraction column is characterized by 1) high throughput, 2) high efficiency, and 3) resistance to fouling. In particular, throughput (flow rate per cross-sectional area) is 2-5 times higher than other representative extraction columns such as perforated columns and agitated extraction columns.

Features

- High throughput

- High-efficiency extraction

- Wide operating range (low turndown ratio)

- Resistance to interface suspended substances (scum) and fouling

- Free from any clogging trouble due to polymerization components

- Simple in structure and easy to maintain

Applications

- Applicable to liquid-liquid extraction and liquid-liquid reactive extraction

- Extraction of aromatics from cracked gasoline and coal light oil

- Extraction of organic compounds and inorganic compounds from reaction solution and aqueous solution

- Liquid-liquid reactive extraction removal of specific components from a mixture

- Extraction of low concentration non-ferrous metals (uranium, cobalt, silver) from aqueous solution

- Oil extraction from aqueous solution

- Augmenting capabilities of existing facilities

- Augmenting capabilities of sieve tray towers, packed columns, agitated extraction (RDC (rotating contactor),

ARDC (asymmetric rotating disc contactor), Oldshue-Rushton column) by tray/internal exchange

- Augmenting capabilities of sieve tray towers, packed columns, agitated extraction (RDC (rotating contactor),

- Intensification of process performance

Experience

- Aromatics extractors (2 units) in Japan

- Organic compound extractors (15 units) in Japan and overseas

- Inorganic compound extractors (1 unit) in Japan

- Liquid-liquid reactor (1 unit) in japan

Awards

- SCEJ (The Society of Chemical Engineering, Japan): Technology Award (2006)

- SSPEJ (The Society of Separation Process Engineers, Japan): Technology Award (2005)

Energy Transition - Gas/Oil/Chemicals

- The World's Most Advanced Energy-saving Condensate Desulfurization Process(JUSTTM Condensate)

- Integrated Hydrogen Desulfurization System - JUST® Refinery -

- Gas Oil Ultra-Deep Desulfurization Process

- Dimethyl Ether (DME) Synthesis Process

- High-Purity Hydrogen Sulfide Production Process

- DTP® Process

- Advanced Dehydration Process for Organic Compounds (Vapor-Phase PSA System)

- High-Throughput and High-Efficiency Extraction Column (WINTRAY®)