Project Management

Unique Project Management System Leads to Successful Project Completion

JGC carries out total project management in all project phases, including design, procurement, construction, operation and maintenance. The project team is led by a project manager, and consists of expert engineers and staff from each discipline, all of whom are fully devoted to the development of the basic plan including schedule, cost, quality and safety. A plant is a complicated integrated system consisting of different elements/components and functions. They shall possess economic efficiency, reliability, safety, higher operability/maintainability and consideration to the environment. In order to satisfy such requirements, the JGC project team having extensive experience and techniques procures equipment, materials, and multi-national manpower resources on a global scale to complete the construction work on schedule. With high-level engineering technologies and a unique project management system, JGC delivers a plant that fully meets the client's desire.

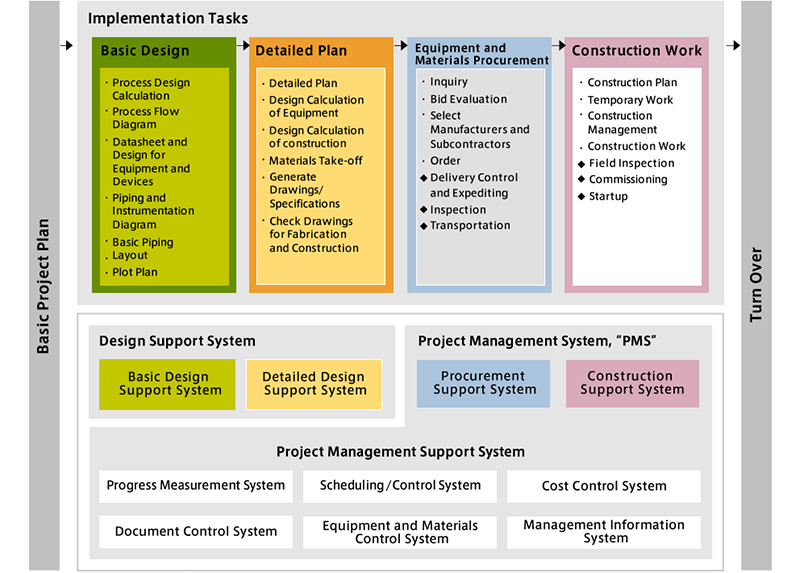

Project Implementation and Support System Concept

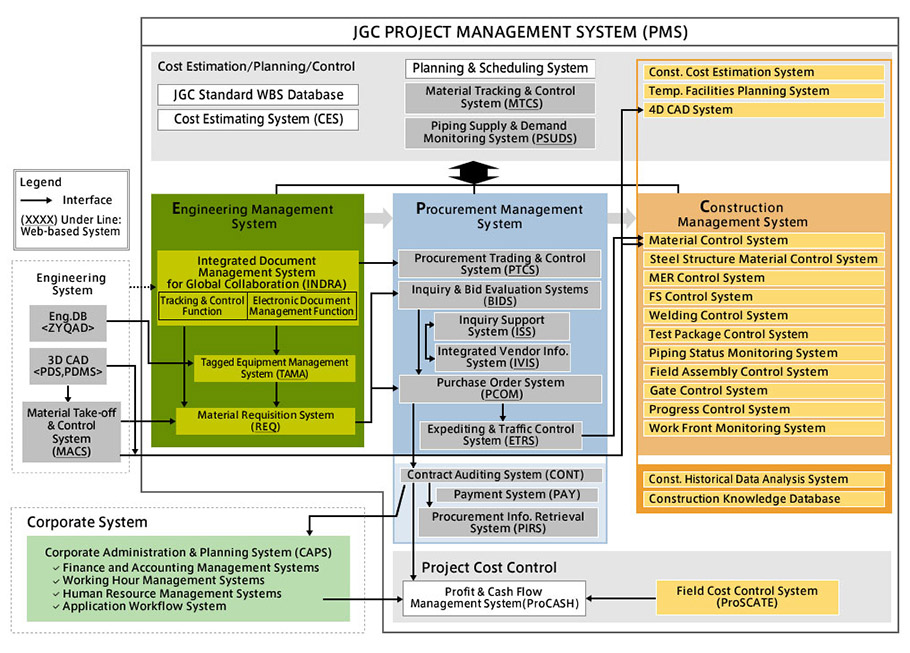

JGC PROJECT MANAGEMENT SYSTEM (PMS)

PMS is a tool to manage various resources including human resources, materials/equipment, financial resources, drawings and specifications, and time during the implementation of the design, procurement, construction, and commissioning under a unified concept (WBS).

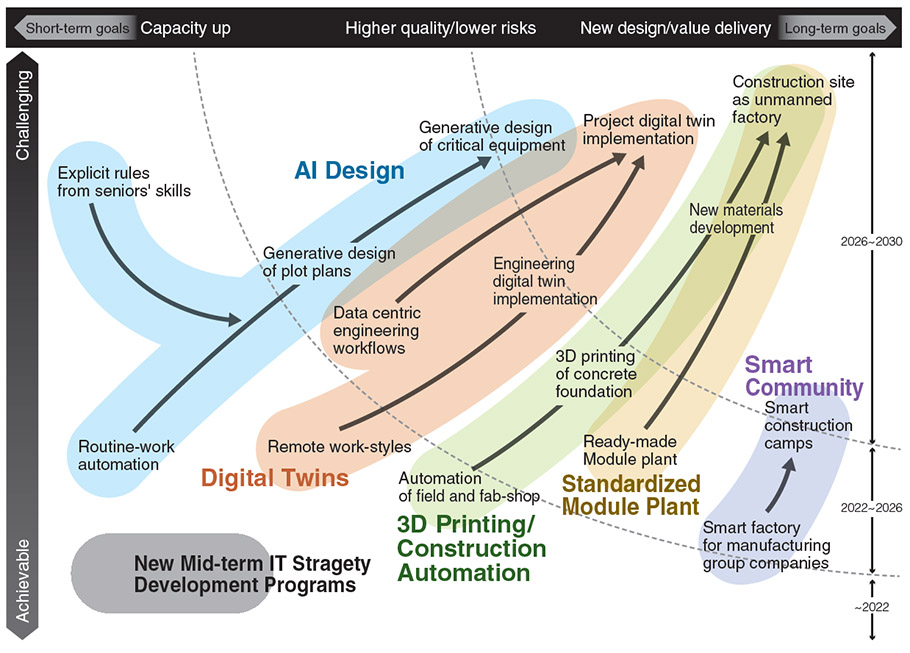

IT Grand Plan 2030

With the future vision of the inclusion of the application of the latest IT advances to manufacturing as a further element in addition to its main EPC business, the JGC Group has created a road-map in the form of its "IT Grand Plan 2030" in December 2018.

With this plan as its guide, we are working to innovate project management by actively utilizing digitalized AI/IoT.

<Plan Outline>

- (1)Innovations in Engineering Capabilities due to AI Design

The aim is to create the ability to optimize the layout of the plant, to automatically select equipment and innovative generative design of process equipment. For these purposes, the reinforcement learning and generative design capabilities of AI will be used. In addition, the knowledge of senior staff will be made into explicit rules so that the engineering check work will be made automatically. - (2)Project Digital Twin and Simulation (Future Prediction)

In the near future, engineering companies will deliver to customers not only the actual plant but also the "digital twin" model in digital space. JGC will also implement digital twins of entire projects and use them to make forecasts and decisions regarding future developments. - (3)Dramatic Improvement at Construction Sites as a result of 3D Printers and Automization of Construction

The automization of construction sites, the use of robots, the introduction of large-scale 3D printers and the development of new materials will bring about a dramatic shortening of the lead time from engineering to construction. - (4)Improvement of Productivity through the Use of Standardization and Modular Constructions Methods

Instead of designing plants from scratch each time, using standardized designs and modular construction will enable us to raise the level of productivity of our engineering, procurement and construction, making it possible to deliver projects in a much shorter time. - (5)Development of Smart Community Technology

Making smart factories with IoT for manufacturing companies in the JGC group is the first step of this innovation. Such technical expertise will also be applied to construction camps. The final goal is to attain the capability to design and build smart infrastructure both in Japan and overseas.

<IT Grand Plan Roadmap>

In the chart, the horizontal axis at the top of the figure indicates the target of activities, while the vertical axis shows the difficulty level of the activities from high to low of each innovation program.