Construction

Where Technology Meets Passion: Ensuring Success for Projects in Remote Regions

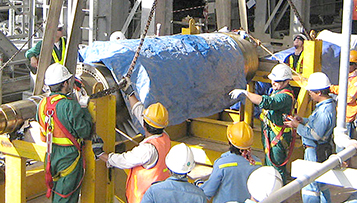

Deserts, jungles, extreme cold, cultural differences-no matter what the regional challenges, and no matter how large the project scale, JGC will fulfill the wishes of the client. This is the pledge of our construction service, and we promise to follow through to the very last day, staying within budget, and abiding by all safety regulations, deadlines, and quality standards.

Effectively combining staff, workers, equipment and materials on a global scale, we draft detailed plans to minimize construction time and costs, while ensuring safety and quality. On site, we introduce appropriate construction methods for each project location and use a construction management system to deploy manpower efficiently.

JGC has many years of experience drafting construction plans and executing construction work for plants involving difficult or unstable circumstances. All our project personnel work as a team to deal with problems clearly and quickly, to achieve the plant's completion on time.

-

1Feasibility Study - Contract Bidding Phase

Situated throughout the world, in various environments, with various purposes, no two plants constructed by JGC are alike. Our database of overseas project experience goes back 50 years, and we apply this know-how to maximal degree, to analyze a plant's unique circumstances and deliver an optimized construction plan and fixed list of costs to support our bid for a project.

-

2Project Start - Beginning of On-site Construction

The project team brings together talented members who are specialists in the respective fields of E (engineering), P (procurement) and C (construction). The construction group in charge of C (construction) is led by a construction manager with extensive field experience and consists of professionals each with knowledge of construction planning, construction contracts, schedule control and other specialties. This group begins the preparations to be able to start the future construction work as soon as possible. For construction work on undeveloped land the group also selects the best subcontractors from around the world to develop makeshift plans, such as setting up the construction camp and offices, and execute large-scale project construction work. In addition, at the early stage of the start of a project the group plans the requirements based on the construction schedule and procedures (known as the Constructability Study) and provides feedback on upstream process design and procurement in order to optimize the entire project.

-

3On-site Construction - Completion

As upstream process design and procurement functions reach their peak, preparations are made for a smooth launch of construction work at the site. Sometimes existing rivers or ponds are relocated while simultaneously the construction site is prepared as environmental protection measures are taken, existing structures are removed and the foundation improved, and the construction camp is set up to receive a large number of personnel.

After actual construction work starts construction tasks and construction quality, schedules and a large amount of personnel and equipment are all well managed. Along with not only this but the timely dispatch and sharing of information with respect to construction progress to the design and procurement groups and the anticipation of possible future problems enables planning of various kinds of appropriate construction actions to execute the construction project.

Needless to say, safety and quality are maintained at the construction site. In recent years we have sites that established worldwide records based on no accidents-no disasters in "100 million hours" (a level of not one person suffering major injury among the 30,000 or more people engaged each day in year-long construction work). Our safety management has earned high praise from our clients.

Uniting JGC's head office, overseas group companies and also a team of 40,000 staff and laborers of different nationalities working at construction sites in each region of the world requires "strong determination and leadership to complete the job." All this is the source of our strong construction execution capabilities in which we take pride.